Briefly describe the distinction between cable core and quality?

Release time:

2020-12-10

Many cores are called multi-core cables. Common multi-core wires are: 10 core, 12 core, 16 core, 24 core, 32 core and so on. Multi-core cable is an upgraded version of single-core cable. As there are more and more occasions for three-phase four-wire power supply, three-phase five-wire power supply and multi-loop power supply in actual use, the requirements for space occupation and laying occasions are also getting higher and higher.

Many cores are called multi-core cables. Common multi-core wires are: 10 core, 12 core, 16 core, 24 core, 32 core and so on. Multi-core cable is an upgraded version of single-core cable. As there are more and more occasions for three-phase four-wire power supply, three-phase five-wire power supply and multi-loop power supply in actual use, the requirements for space occupation and laying occasions are also getting higher and higher. When multiple, multi-layer laying is required, and the occupied space and laying conditions are limited, single-core cables cannot be easily used. Therefore, multi-core cable is developed and quickly into the field of power applications, accepted and used by the majority of users. As there are more and more occasions for three-phase four-wire power supply, three-phase five-wire power supply and multi-loop power supply in actual use, the requirements for space occupation and laying occasions are also getting higher and higher. When multiple, multi-layer laying is required, and the occupied space and laying conditions are limited, single-core cables cannot be easily used.

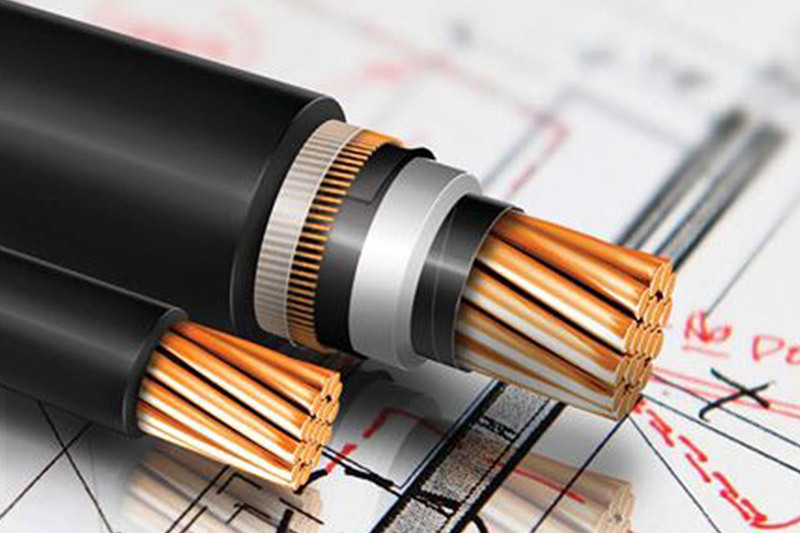

Armored cable: a layer of metal or other substances (depending on the environment in which the cable is laid) is added to the outer insulating layer of the cable to protect the cable from being damaged by external mechanical forces, corroded by chemical gases, etc. This layer is the armored layer, and such cables are called armored cables. Armored cable mechanical protection layer can be added to any structure of the cable, to increase the mechanical strength of the cable, improve the ability to resist erosion, is vulnerable to mechanical damage and erosion of the area and the design of the telephone cable. It can be laid in any way, which is more suitable for direct burial laying in rock areas.

The definition of armored cable is to install a layer of metal protection on the outermost surface of the product to avoid damage to the internal utility layer during transportation and installation. In the armor of the cable, a layer of insulating sheath is usually added to the outside. The materials of armored cables include steel tape, steel wire, copper tape, tinned steel wire, etc., and their selection is mainly based on the customer's use environment and requirements.

The role of armored cable: used to transmit electrical energy, information and electromagnetic energy conversion of electrical wire products.

How to distinguish between good and bad cable

1. Look at the appearance and certificate: We look at the certification certificate of the quality system required by the manufacturer to see if the certificate is standardized. Whether there is a factory name, address, inspection seal, production date, etc. But also to see whether the cable itself has a trademark, specifications, voltage and so on. Also look at the cross section of the wire copper core, high-quality copper color bright, soft color.

Weighing: Good quality wires are generally within the specified weight range. For example, the commonly used cross-sectional area is 1. 5 square plastic insulated single strand copper core wire, each 100m weight is 1. 8~1. 9KG,2. 5 square plastic insulated single strand copper core wire, the weight of each 100m is 3~3. 1kg. The poor quality of the cable weight is insufficient, or the length is not enough, or the copper core of the wire is too much impurities.

3. Try: Take a piece of wire head and bend it repeatedly. Wires with soft hand feeling, good strength, plastic or rubber elasticity and no cracks in the wire insulation are generally national standard wires.

4. Look at the price: Because poor wires are generally produced with bad materials to reduce costs, the price is generally one of the important means to distinguish.

5, look at the copper: qualified copper core wire copper core is purple, shiny, feel good. Inferior copper cores are purple-black or yellow, white, with many impurities, poor mechanical strength, insufficient flexibility, and will break with a little force. And there are often short lines in the wires. We usually peel off the wire head and scratch it on the white paper with the copper core. If there is black residue on the white paper, it means that the copper core has more impurities, which is non-standard wire.

TAG:

Previous

Previous:

Recommend