VLV22 type 0.6/1KV PVC Insulated Power Cable

Classification:

Product Description

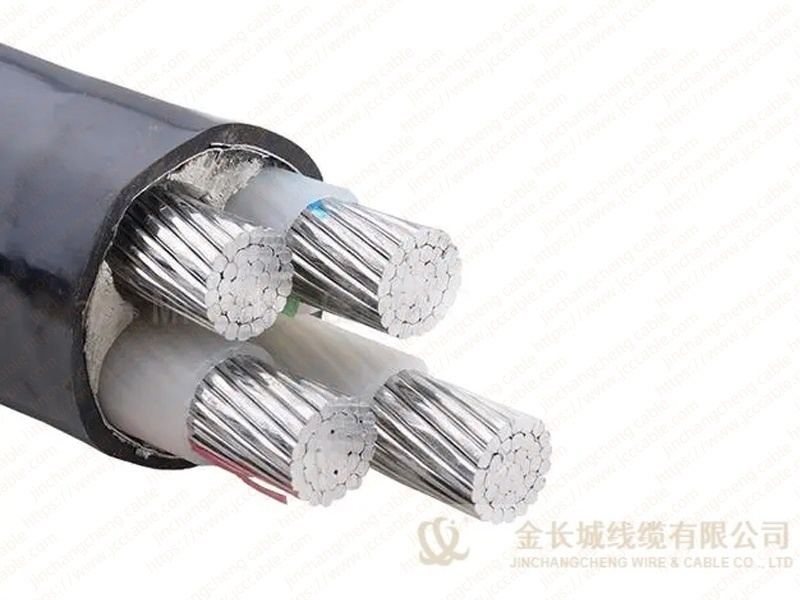

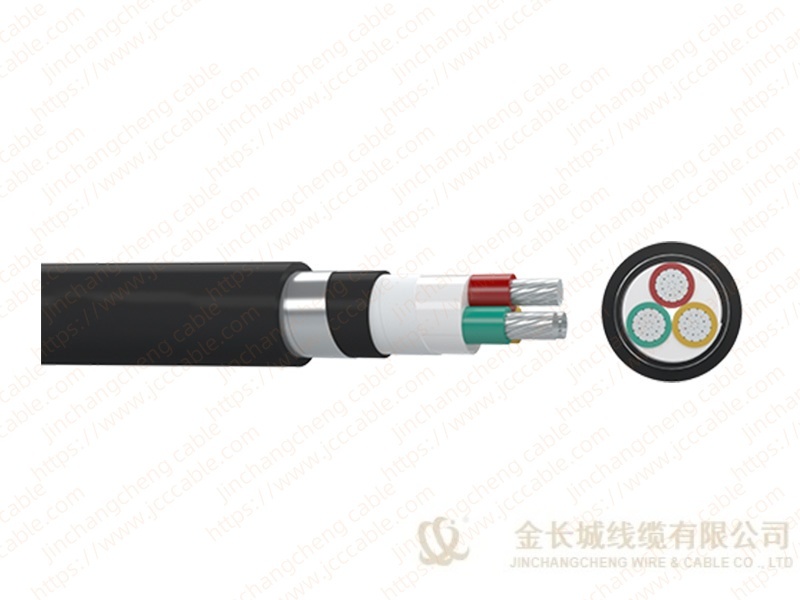

Low Voltage(0.6/1KV) Power Cable-VLV22

The Aluminum Core PVC Insulated Steel Tape Armored PVC Sheathed Power Cable is a reliable and cost-effective solution for power transmission in various industrial and residential applications. This cable is designed to offer excellent electrical performance while providing robust mechanical protection, making it ideal for challenging environments, including underground installations and areas requiring additional security against physical damage.

Standard

IEC 60228 Conductors of Insulate Cables

IEC 60502-1 Power Cables with Extruded Insulation and Their Accessories for Rated Voltages from 1kV(Um=1.2kV) up to 30kV(Um=36kV) - Part 1: Cables for Rated Voltages of 1kV (Um=1.2kV) and 3kV(Um=3.6kV)

Construction

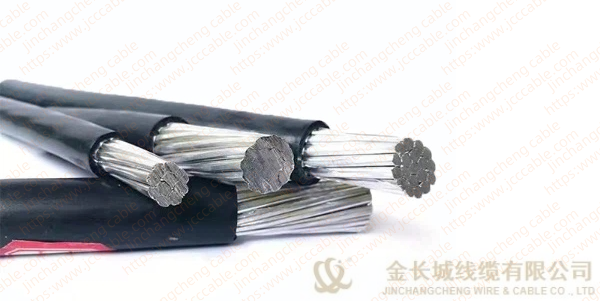

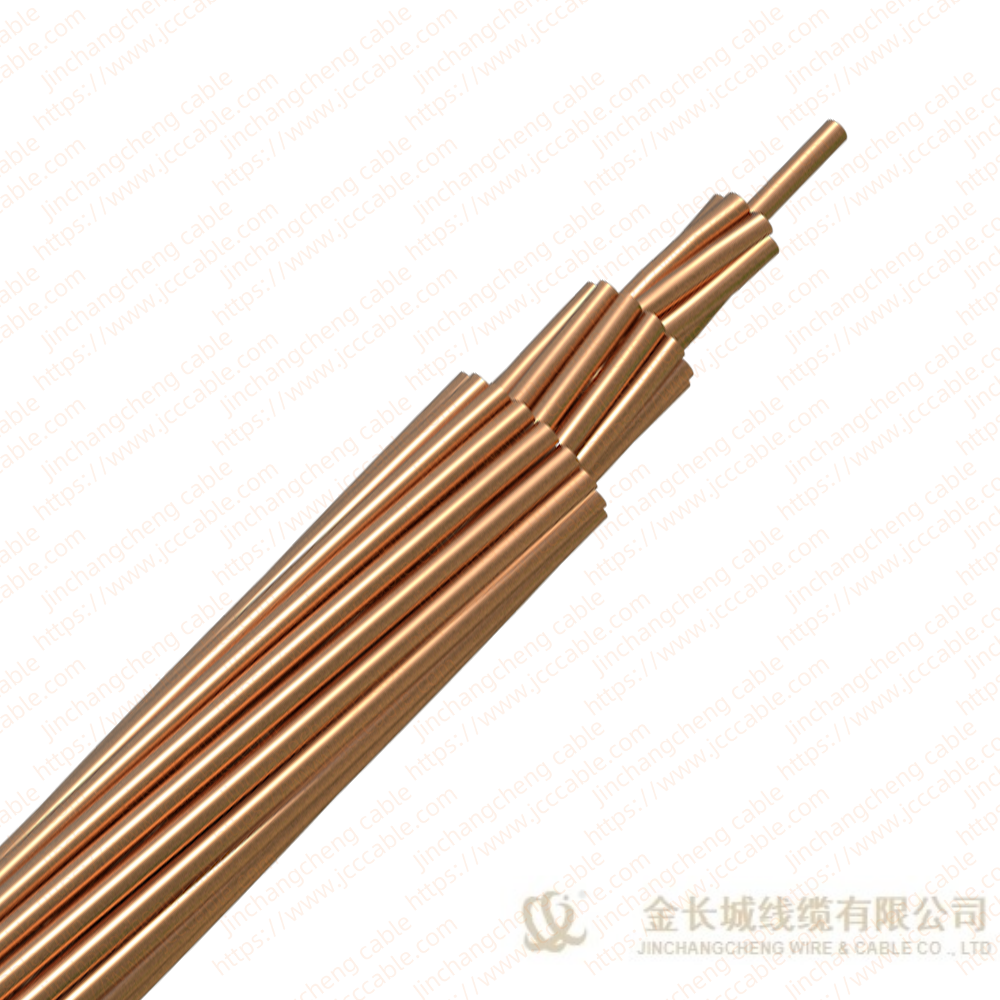

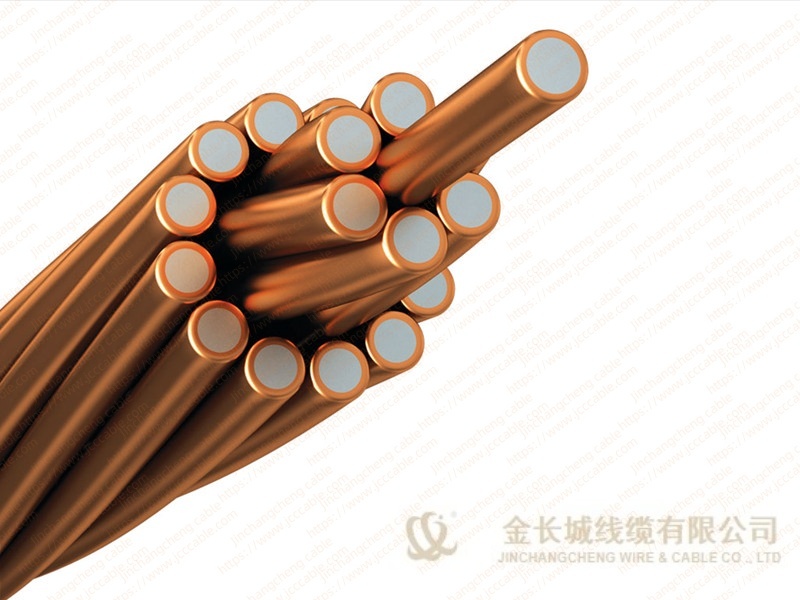

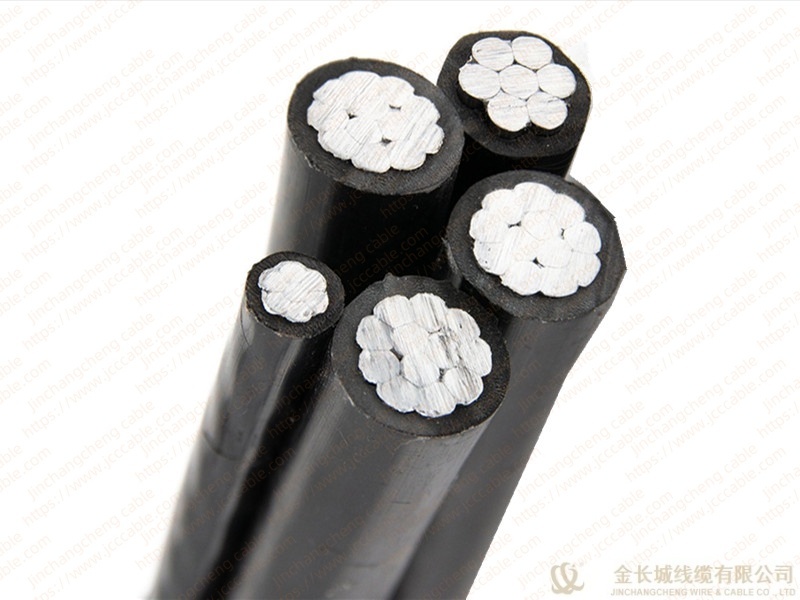

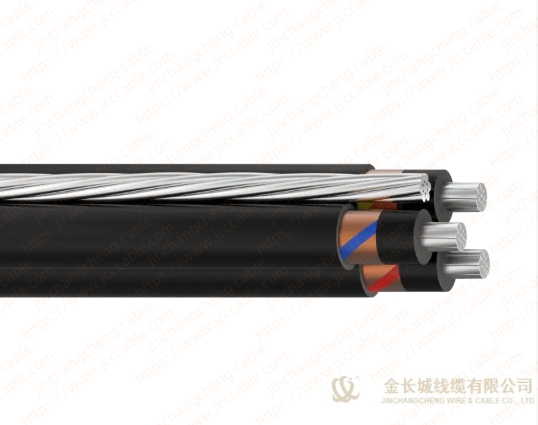

● Conductor: Aluminum, class 1 or class 2, solid or stranded, circular or circular compacted conductors

● Insulation: Polyvinyl chloride PVC

● Filler: Non-hygroscopic material

● Binder: Non-hygroscopic material

● Inner sheath: Polyvinyl chloride PVC

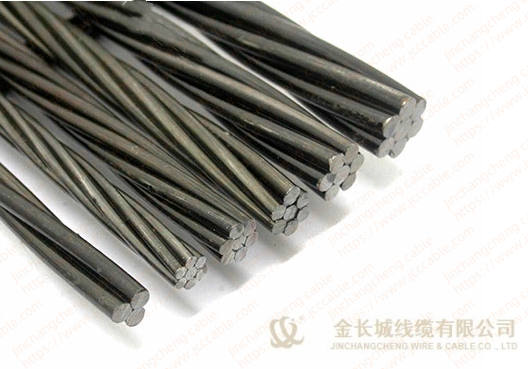

● Armour: Steel tape

● Outer sheath: Polyvinyl chloride PVC

Technical Specifications

Voltage level: Up to 0.6/1 kV

Conductor material: Aluminum

Insulation material: Polyvinyl chloride (PVC)

Armor type: Galvanized steel tape for additional mechanical protection

Sheath material: PVC outer sheath for enhanced durability

Compliance with standards: Products comply with international standards IEC 60502, BS 5467 and GB/T 12706.

Usage Characteristics

Maximum operating temperature of conductor: 70℃

Maximum short-circuit temperature of conductor: 160℃, maximum duration 5 seconds

Installation and laying temperature: minimum installation and laying temperature is not less than 0℃

Laying environment temperature: when laid in air, the environment temperature is 40℃

Laying environment temperature in soil: 25℃

Advantage:

Excellent durability: Our cables are designed to withstand harsh environments, moisture, mechanical stress and chemical corrosion, and have a longer service life.

Cost-effective: The aluminum core is more economical than copper core, but it also guarantees performance and safety.

Wide application: Suitable for underground and above-ground installation, suitable for multiple industries such as energy, construction and manufacturing.

Compliant with international standards: Certified by IEC, BS and GB standards, ensuring safety and reliability worldwide.

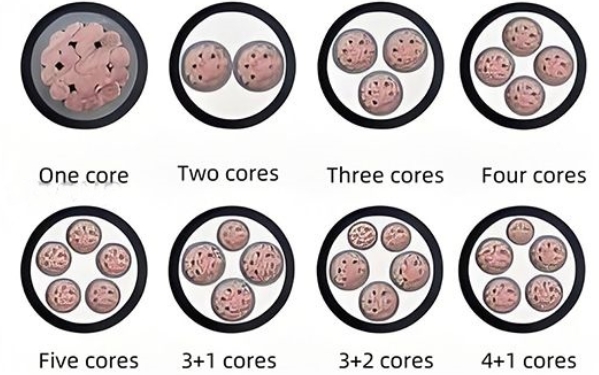

Product structure and parameter

No. of Cores and Nominal Cross Section | Min. Number of Wires | Nominal Insulation Thickness | Nominal | Nominal | Approx. | Approx. Weight | Max. D.C. Resistance of Conductor |

No. × mm² | No. | mm | mm | mm | mm | kg/km | Ω/km |

2×2.5 | 1 | 0.8 | 0.2 | 1.8 | 13.4 | 246 | 12.1 |

2×4 | 1 | 1.0 | 0.2 | 1.8 | 15.2 | 306 | 7.41 |

2×6 | 1 | 1.0 | 0.2 | 1.8 | 16.2 | 350 | 4.61 |

2×10 | 6 | 1.0 | 0.2 | 1.8 | 18.7 | 429 | 3.08 |

2×16 | 6 | 1.0 | 0.2 | 1.8 | 20.3 | 522 | 1.91 |

2×25 | 6 | 1.2 | 0.2 | 1.8 | 23.5 | 684 | 1.20 |

2×35 | 6 | 1.2 | 0.2 | 1.8 | 25.5 | 804 | 0.868 |

3×2.5 | 1 | 0.8 | 0.2 | 1.8 | 14.0 | 271 | 12.1 |

3×4 | 1 | 1.0 | 0.2 | 1.8 | 15.8 | 343 | 7.41 |

3×6 | 1 | 1.0 | 0.2 | 1.8 | 16.9 | 396 | 4.61 |

3×10 | 6 | 1.0 | 0.2 | 1.8 | 19.7 | 491 | 3.08 |

3×16 | 6 | 1.0 | 0.2 | 1.8 | 21.4 | 607 | 1.91 |

3×25 | 6 | 1.2 | 0.2 | 1.8 | 24.8 | 808 | 1.20 |

4×2.5 | 1 | 0.8 | 0.2 | 1.8 | 14.8 | 307 | 12.1 |

4×4 | 1 | 1.0 | 0.2 | 1.8 | 16.9 | 394 | 7.41 |

4×6 | 1 | 1.0 | 0.2 | 1.8 | 18.2 | 458 | 4.61 |

4×10 | 6 | 1.0 | 0.2 | 1.8 | 21.2 | 573 | 3.08 |

4×16 | 6 | 1.0 | 0.2 | 1.8 | 23.2 | 717 | 1.91 |

4×25 | 6 | 1.2 | 0.2 | 1.8 | 27.0 | 965 | 1.20 |

4×35 | 6 | 1.2 | 0.2 | 1.9 | 29.6 | 1169 | 0.868 |

5×2.5 | 1 | 0.8 | 0.2 | 1.8 | 15.8 | 345 | 12.1 |

5×4 | 1 | 1.0 | 0.2 | 1.8 | 18.1 | 447 | 7.41 |

5×6 | 1 | 1.0 | 0.2 | 1.8 | 19.5 | 524 | 4.61 |

5×10 | 6 | 1.0 | 0.2 | 1.8 | 22.9 | 662 | 3.08 |

5×16 | 6 | 1.0 | 0.2 | 1.8 | 25.1 | 834 | 1.91 |

5×25 | 6 | 1.2 | 0.2 | 1.9 | 29.6 | 1147 | 1.20 |

5×35 | 6 | 1.2 | 0.2 | 1.9 | 33.0 | 1426 | 0.868 |

3×4+1×2.5 | 1/1 | 1.0/0.8 | 0.2 | 1.8 | 16.4 | 371 | 7.41/12.1 |

3×6+1×4 | 1/1 | 1.0/1.0 | 0.2 | 1.8 | 17.9 | 442 | 4.61/7.41 |

3×10+1×6 | 6/1 | 1.0/1.0 | 0.2 | 1.8 | 20.5 | 544 | 3.08/4.61 |

3×16+1×10 | 6/6 | 1.0/1.0 | 0.2 | 1.8 | 22.7 | 680 | 1.91/3.08 |

3×25+1×16 | 6/6 | 1.2/1.0 | 0.2 | 1.8 | 26.1 | 901 | 1.20/1.91 |

4×4+1×2.5 | 1/1 | 1.0/0.8 | 0.2 | 1.8 | 17.7 | 426 | 7.41/12.1 |

4×6+1×4 | 1/1 | 1.0/1.0 | 0.2 | 1.8 | 19.2 | 509 | 4.61/7.41 |

4×10+1×6 | 6/1 | 1.0/1.0 | 0.2 | 1.8 | 22.2 | 634 | 3.08/4.61 |

4×16+1×10 | 6/6 | 1.0/1.0 | 0.2 | 1.8 | 24.6 | 799 | 1.91/3.08 |

4×25+1×16 | 6/6 | 1.2/1.0 | 0.2 | 1.8 | 28.5 | 1072 | 1.20/1.91 |

4×35+1×16 | 6/6 | 1.2/1.0 | 0.2 | 1.9 | 30.9 | 1268 | 0.868/1.91 |

Application

Underground power distribution: Designed for underground installation, it provides protection against physical damage and moisture.

Industrial power networks: Suitable for heavy-duty applications in industrial facilities such as factories and refineries, and can maintain stable operation in harsh environments.

Power stations and substations: Suitable for power transmission and distribution in energy infrastructure, ensuring reliable performance in low-voltage and medium-voltage applications.

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products