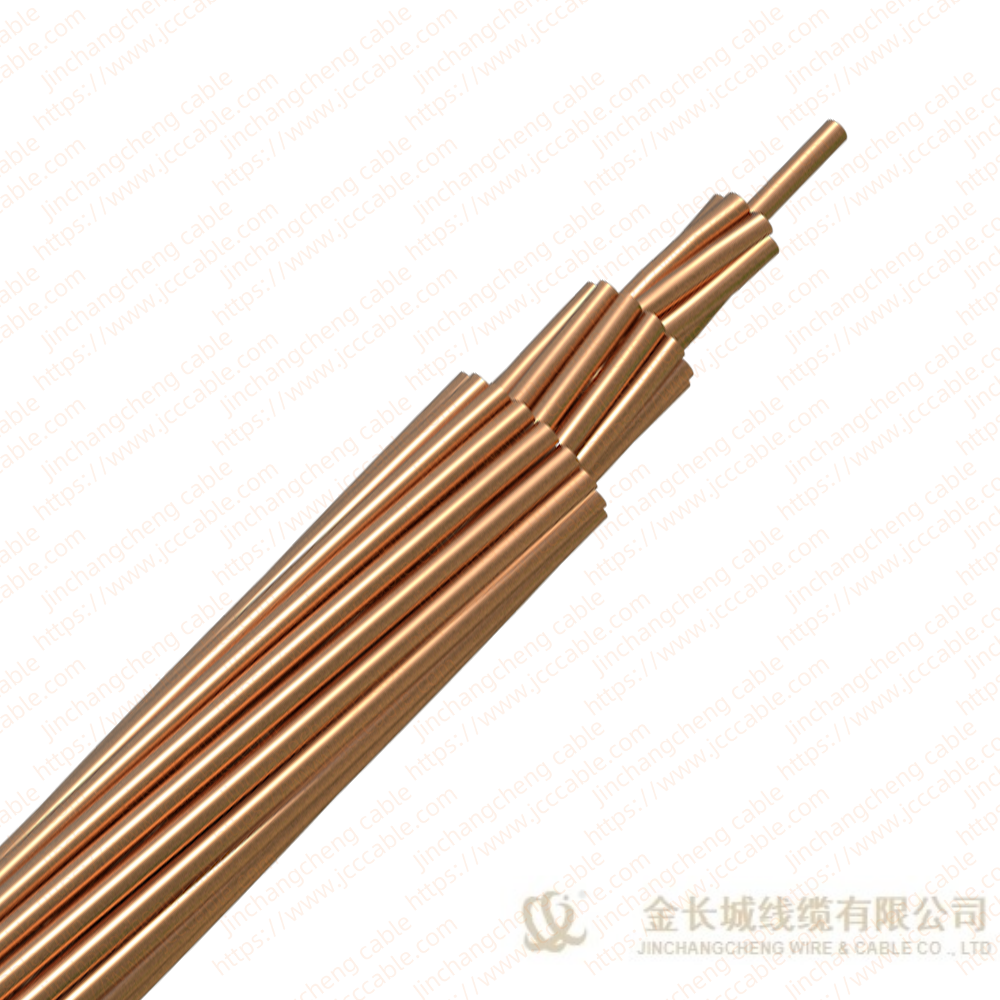

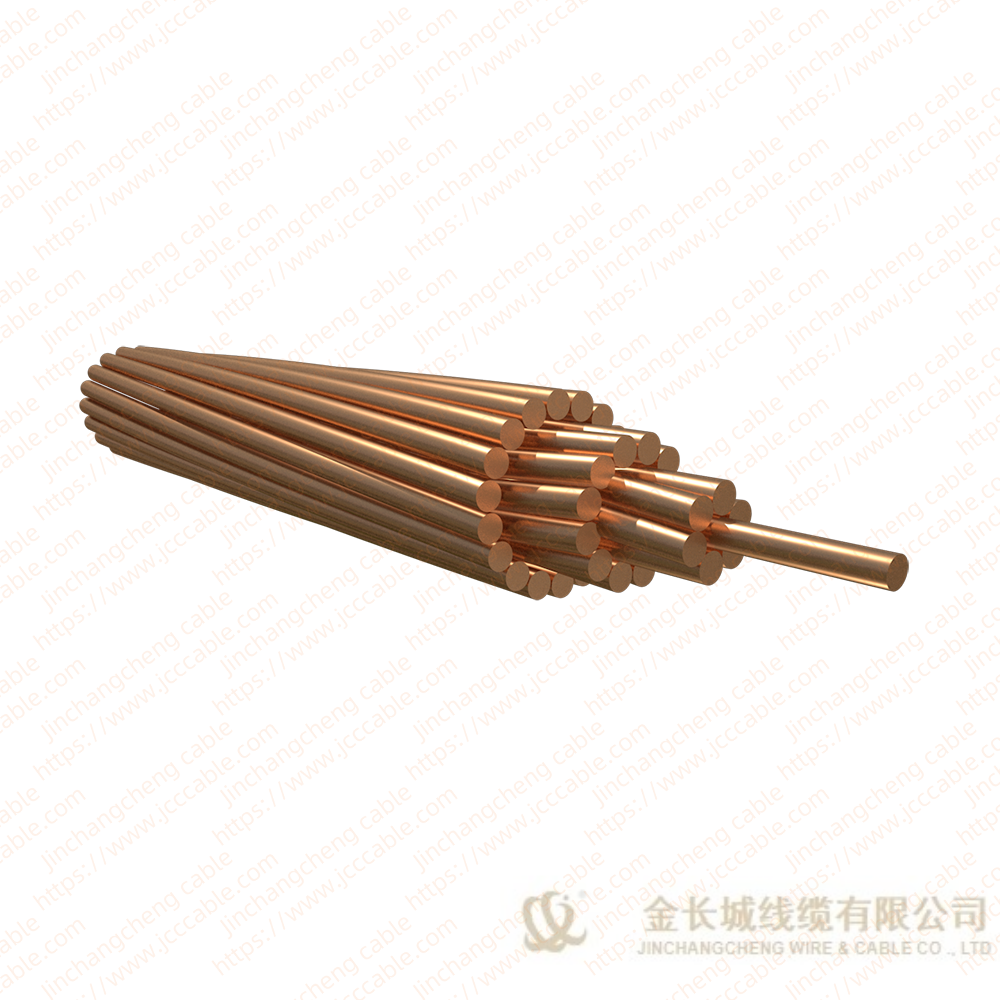

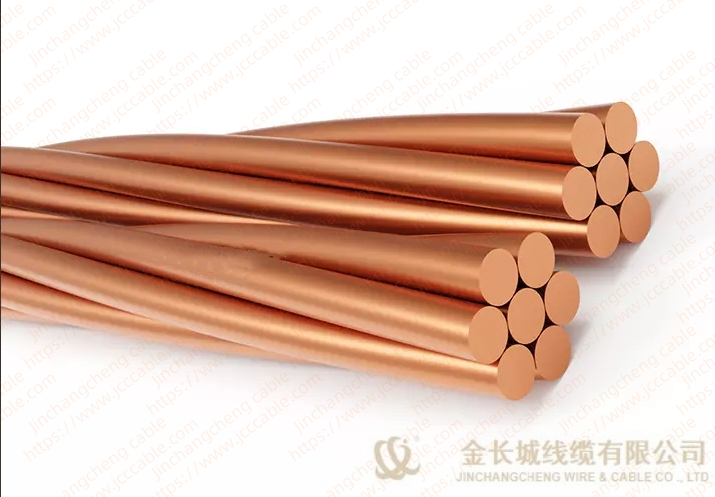

Bare copper stranded conductor

Classification:

Product Description

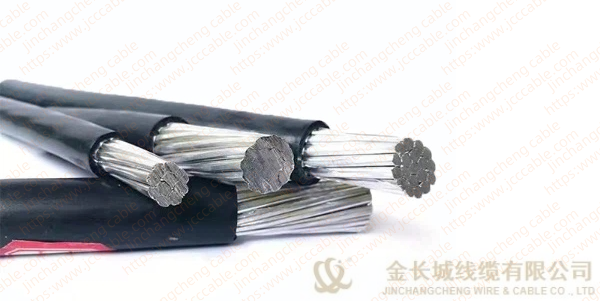

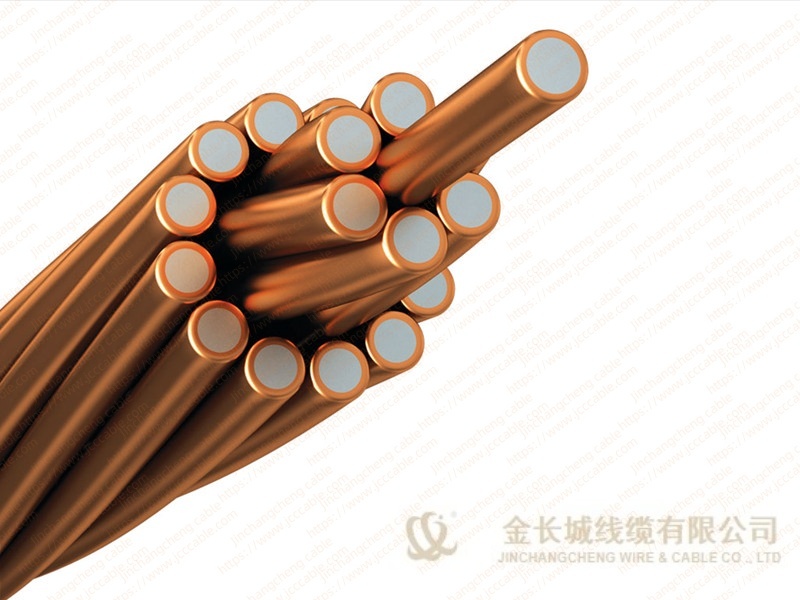

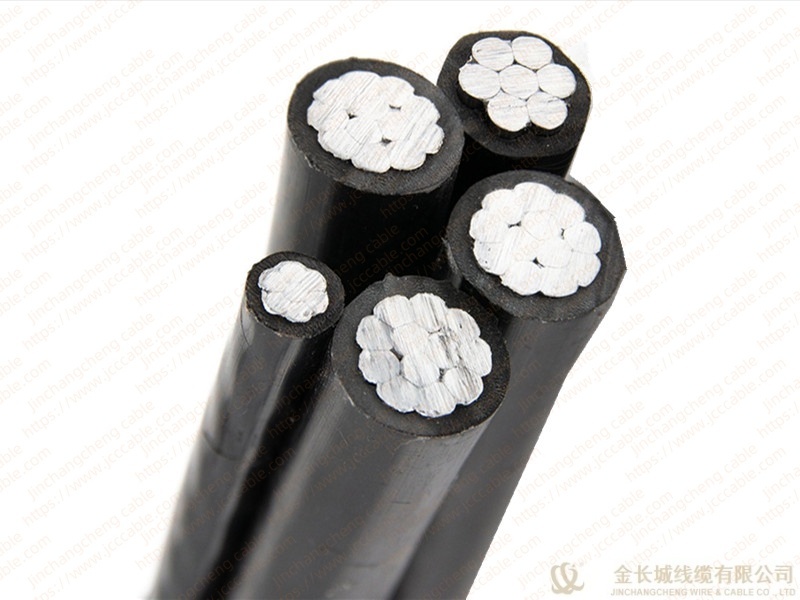

The bare copper strand conductor also are known as bare copper conductor, ground copper and bare copper strand. They have two main types, the hard drawn and soft drawn (tinned soft drawn).

The stranded bare copper is the connection of electrical equipment for transmission and distribution (such as transformer, the electric cabinet of the electric furnace), electronic and electrical equipment, and SCR components, and can also be used as ground wire for electrical operation.

Standard

BS EN 60228 / IEC 60228

Advantages:

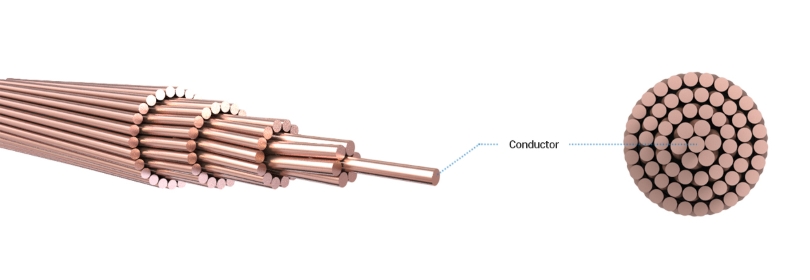

Excellent conductivity: High-purity copper ensures low resistance of the wire and reduces energy loss.

Good flexibility: The twisted structure makes the wire flexible and easy to install and wire.

Strong corrosion resistance: Copper has good corrosion resistance and is suitable for a variety of environmental conditions.

High mechanical strength: The twisted design enhances the tensile strength of the wire and adapts to complex installation environments.

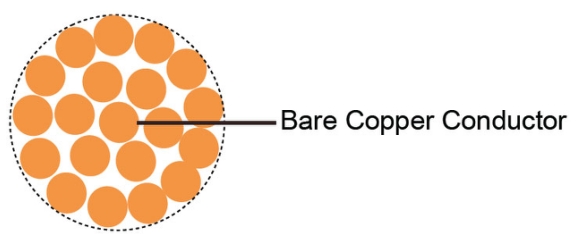

Product Features

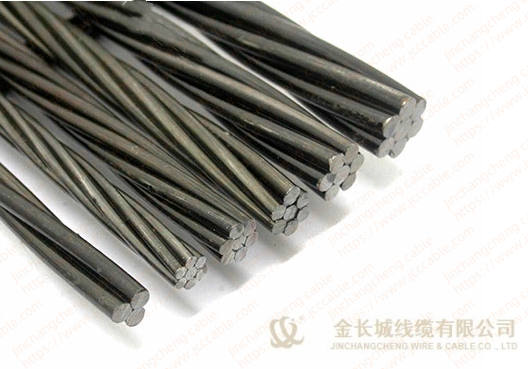

High Tensile Strength

Hard drawn copper offers excellent resistance to mechanical stress, sagging, and breakage—ideal for long-span and overhead applications.

Stranded Flexibility

The concentric stranded design increases flexibility, making installation easier and improving resistance to vibration and bending stress.

Good Electrical Conductivity

While slightly lower than annealed copper, hard drawn copper still provides efficient power transmission for medium to high-voltage systems.

Corrosion Resistance

Bare copper provides natural resistance to corrosion, extending service life in outdoor and urban environments.

Low Maintenance

Suitable for applications where long-term durability and minimal maintenance are required.

Technical Infomation

Construction characteristics | |

Conductor material | Electrolytic, stranded and bare copper |

Conductor class | Class 2 according to BS EN60228 |

Usage characteristics | |

Minimum Installation Temperature | 0°C |

Maximum Installation Temperature | 60°C |

Minimum Operating Temperature | -15°C |

Maximum Operating Temperature | 70°C |

Maximum conductor temperature | 90°C |

Linear resistance @20°C | According to BS EN60228 / IEC 60228 |

Short-circuit max. conductor temperature | 370°C |

Mechanical characteristics | |

Min. Bending Radius | 35mm^2 up to 400mm^2 = 6 x OD |

Product structure and parameter

Solid

Size | Section | Number | Wire Diameter | Conducto | Resistance | Minimum | Minimum | Minimum Tensile | Total | |

AWG/MCM | Cmils | mm² | mm | mm | Q/km | % | kg/mm² | kg | kg/km | |

4 | 41740 | 21.1 | 7 | 1.96 | 5.88 | 0.865 | 1.1 | 46.4 | 883 | 192 |

2 | 66360 | 33.6 | 7 | 2.47 | 7.42 | 0.544 | 1.2 | 45.4 | 1373 | 305 |

1/0 | 105600 | 53.5 | 19 | 1.89 | 9.47 | 0.342 | 1.1 | 46.4 | 2234 | 485 |

2/0 | 133100 | 67.4 | 19 | 2.13 | 10.6 | 0.271 | 1.1 | 45.9 | 2785 | 611 |

4/0 | 211600 | 107.2 | 19 | 2.68 | 13.4 | 0.171 | 1.2 | 45.4 | 4379 | 972 |

250 | 250000 | 126.7 | 37 | 2.09 | 14.6 | 0.144 | 1.1 | 45.9 | 5231 | 1149 |

300 | 300000 | 152.0 | 37 | 2.29 | 16 | 0.120 | 1.1 | 45.9 | 6278 | 1379 |

350 | 350000 | 177.3 | 37 | 2.47 | 17.3 | 0.103 | 1.2 | 45.4 | 7243 | 1609 |

400 | 400000 | 202.7 | 37 | 2.64 | 18.5 | 0.090 | 1.2 | 45.4 | 8277 | 1838 |

500 | 500000 | 253.4 | 37 | 2.95 | 20.7 | 0.072 | 1.3 | 44.9 | 10230 | 2298 |

Class A

Nominal | Number | Overal | Maximum |

| Allowable | Cable | Standar |

mm | No./mm | mm | Q/km | kgf | A | kg/km | m |

10 | 7/1.35 | 4.05 | 1.8054 | 438 | 90 | 90 | 1000/R |

16 | 7/1.70 | 5.10 | 1.1385 | 694 | 125 | 143 | 1000/R |

25 | 7/2.14 | 6.42 | 0.7185 | 1076 | 160 | 227 | 1000/R |

35 | 7/2.52 | 7.56 | 0.5181 | 1459 | 200 | 314 | 1000/R |

50 | 7/3.02 | 9.06 | 0.3589 | 2095 | 250 | 452 | 1000/R |

50 | 19/1.78 | 8.90 | 0.3825 | 2021 | 250 | 428 | 1000/R |

70 | 19/2.14 | 10.70 | 0.2646 | 2921 | 310 | 618 | 1000/R |

95 | 19/2.52 | 12.60 | 0.1918 | 3961 | 380 | 858 | 1000/R |

120 | 19/2.85 | 14.25 | 0.1492 | 5067 | 440 | 1097 | 1000/R |

150 | 37/2.25 | 15.75 | 0.1238 | 6289 | 510 | 1334 | 1000/R |

Application

Power transmission: used for the erection of high-voltage and low-voltage power lines to ensure a stable power supply.

Electronic equipment connection: used for signal transmission and power connection inside electronic equipment to ensure the reliability of data transmission.

Building wiring: used for electrical wiring inside buildings to meet lighting and power needs.

Automobile and transportation: used in automobile and railway systems to connect electrical systems to ensure safe operation.

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products