ACAR-Aluminum Conductor Alloy Reinforced

Key words:

Classification:

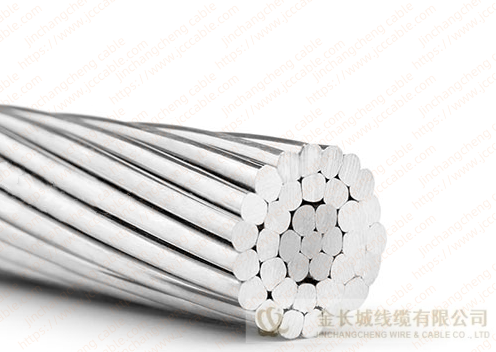

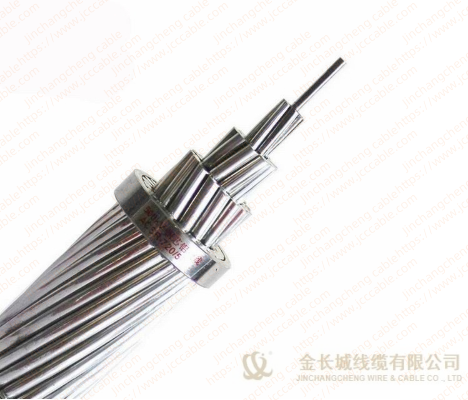

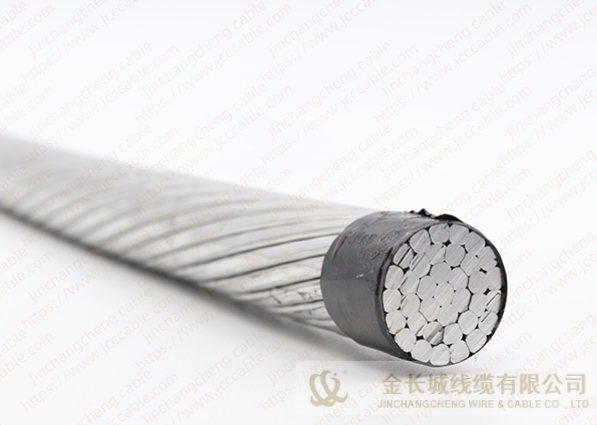

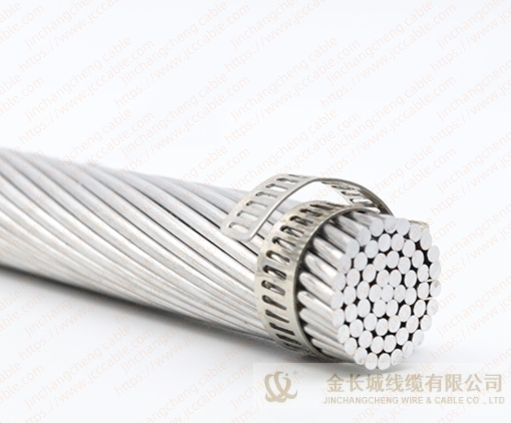

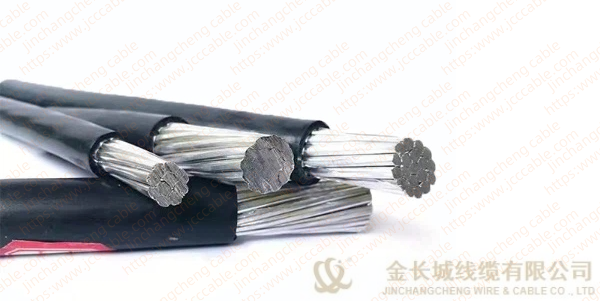

Product Description

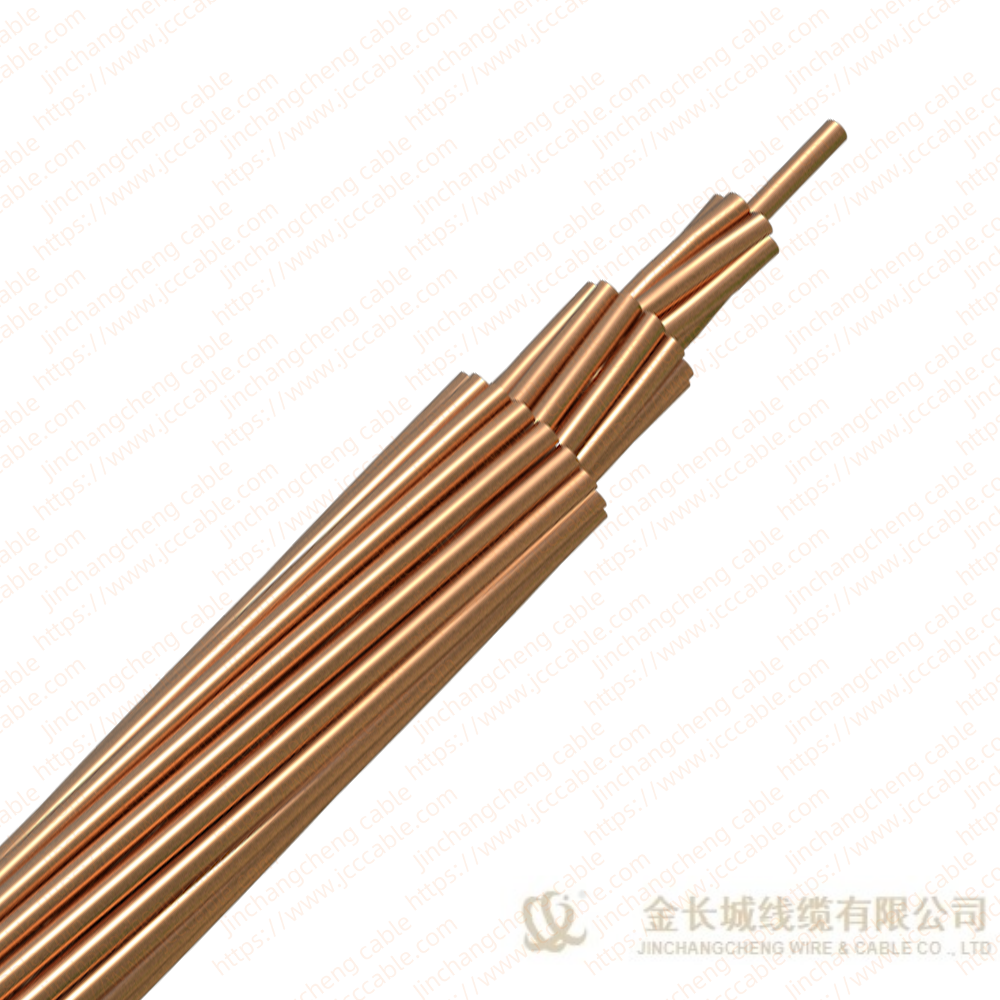

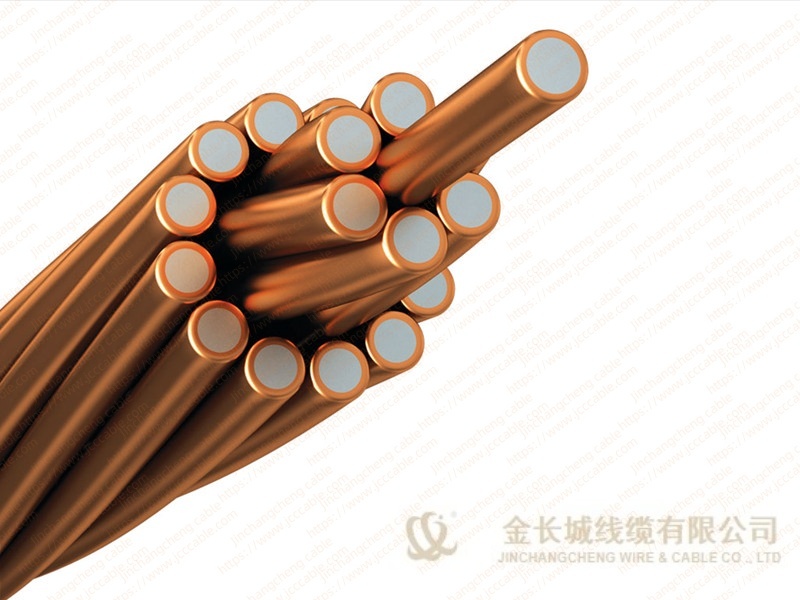

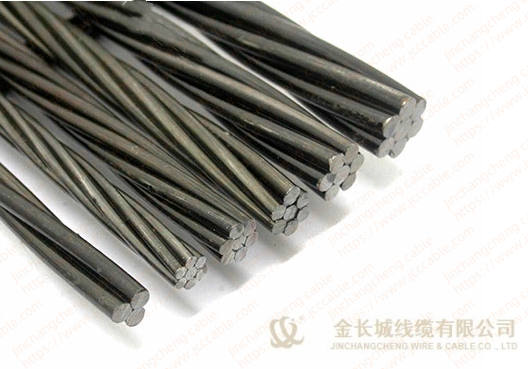

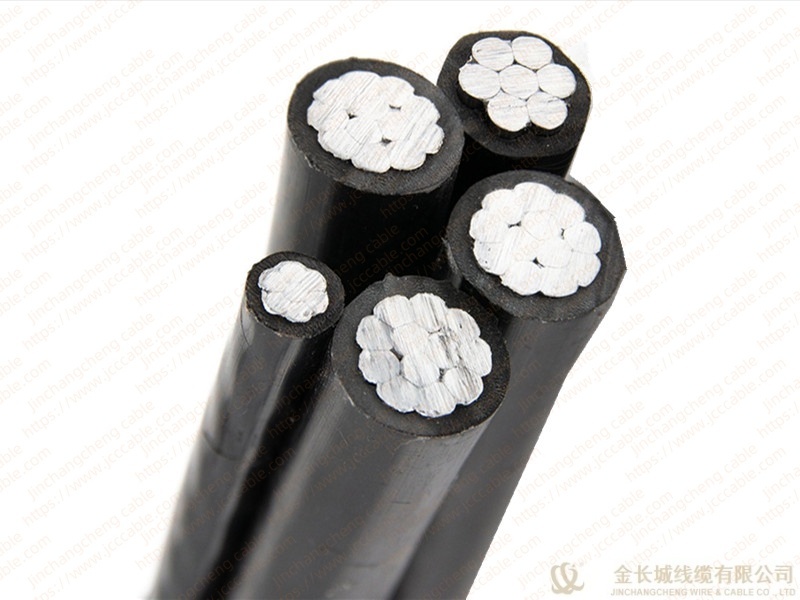

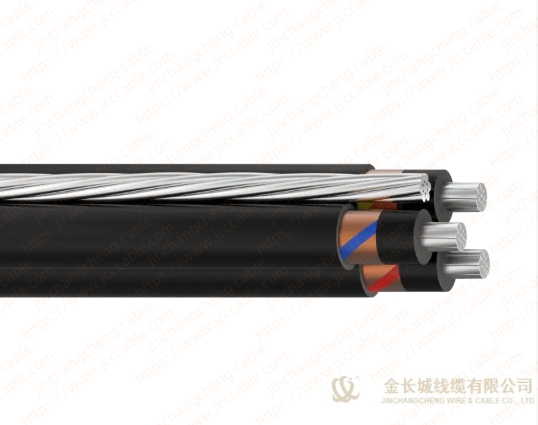

ACAR is a type of overhead insulated wire made of aluminum alloy. It is a combination of ACSR wire and AAAC wire, which not only combines the strength of ACSR wire and the uniformity of conductor gap, but also has the lightweight and corrosion resistance of AAAC wire. ACAR wires have the characteristics of adapting to high altitude, rainy years, and cold conditions, and are suitable for power transmission in mountainous areas and the construction of earth power equipment.

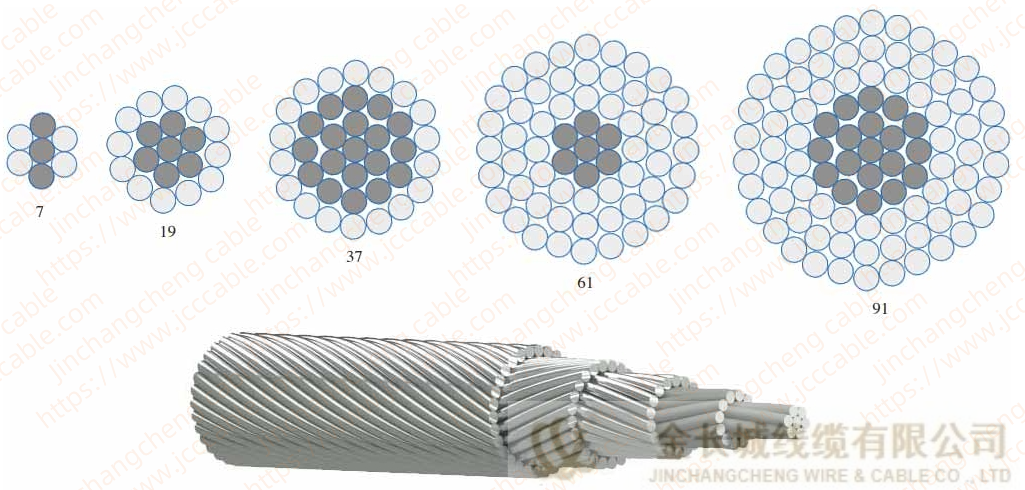

As a kind of energy saving conductor, aluminium conductor alloy reinforced core stranded wire is mainly used for power transmission and distribution in UHV overhead transmission lines. Aluminium alloy core stranded wire can improve the transmission power and save energy consumption. Under the same outer diameter conditions, it is smaller than the DC resistance of the steel core aluminum strand wire, the load can be increased by 10%-25%, effectively reduce the line loss. In addition, the aluminum alloy core aluminum strand is not only easy to install and construct, but also has no hysteresis loss and eddy current loss, energy saving and environmental protection benefits are obvious, and has anti-corrosion function.

Standard

• IEC 61089 Round wire concentric lay overhead electrical stranded conductors

• GB 1179 Round wire concentric lay overhead electrical stranded conductors

Product advantage

- Optimized Strength-to-Weight Ratio: ACAR conductors offer a superior strength-to-weight ratio compared to many other conductor types, including ACSR. This allows for longer spans between support structures, reducing overall infrastructure costs.

- Higher Current Capacity (Ampacity): For a given weight, ACAR conductors can often carry a higher current (ampacity) than ACSR conductors, leading to more efficient power transmission.

- Balanced Performance: They provide an excellent equilibrium between high mechanical strength and efficient electrical conductivity, ensuring reliable and stable power delivery.

- Good Corrosion Resistance: Both aluminum and aluminum alloys inherently offer good resistance to corrosion, contributing to the conductor's longevity in various environmental conditions.

Product structure and parameter

ACAR/A1/A2 IEC 61089 | ||||||||||

Code Number | Diameter | No.of Wires | Areas | Linear Mass | Rated Strength | D.C. Resistance | ||||

Wire | Cond. | A1 | A2 | A1 | A2 | Total | ||||

| mm | mm | No. | No. | mm² | mm² | mm² | kg/km | KN | Ω/km |

16 | 1.76 | 5.28 | 4 | 3 | 9.73 | 7.3 | 17 | 46.6 | 3.85 | 1.7896 |

25 | 2.2 | 6.6 | 4 | 3 | 15.2 | 11.4 | 26.6 | 72.8 | 5.93 | 1.1453 |

40 | 2.78 | 8.35 | 4 | 3 | 24.3 | 18.3 | 42.6 | 116.5 | 9.25 | 0.7158 |

63 | 3.49 | 10.5 | 4 | 3 | 38.3 | 28.7 | 67.1 | 183.5 | 14.38 | 0.4545 |

100 | 4.4 | 13.2 | 4 | 3 | 60.8 | 45.6 | 106 | 291.2 | 22.52 | 0.2863 |

125 | 2.97 | 14.9 | 12 | 7 | 83.3 | 48.6 | 132 | 362.7 | 27.79 | 0.2302 |

160 | 3.36 | 16.8 | 12 | 7 | 107 | 62.2 | 169 | 464.2 | 35.04 | 0.1798 |

ACAR/A1/A3 IEC 61089 | ||||||||||

Code Number | Diameter | No.of Wires | Areas | Linear Mass | Rated Strength | D.C. Resistance | ||||

Wire | Cond. | A1 | A2 | A1 | A2 | Total | ||||

| mm | mm | No. | No. | mm² | mm² | mm² | kg/km | KN | Ω/km |

16 | 1.76 | 5.29 | 4 | 3 | 9.78 | 7.33 | 17.1 | 46.8 | 4.07 | 1.7896 |

25 | 2.21 | 6.62 | 4 | 3 | 15.3 | 11.5 | 26.7 | 73.1 | 6.29 | 1.1453 |

40 | 2.79 | 8.37 | 4 | 3 | 24.4 | 18.3 | 42.8 | 117 | 9.82 | 0.7158 |

63 | 3.50 | 10.5 | 4 | 3 | 38.5 | 28.9 | 67.4 | 184.3 | 14.8 | 0.4545 |

100 | 4.41 | 13.2 | 4 | 3 | 61.1 | 45.8 | 107 | 292.5 | 23.49 | 0.2863 |

125 | 2.98 | 14.9 | 12 | 7 | 83.7 | 48.8 | 132 | 364.1 | 29.29 | 0.2302 |

160 | 3.37 | 16.9 | 12 | 7 | 107 | 62.5 | 170 | 466 | 36.95 | 0.1798 |

ACAR (JL/LHA2, JL1/LHA2) GB/T 1179 | |||||||||||||

Code Number | Calculated Area | No.of Wires | Wire Diameter | Diameter | Linear Mass | Rated Strength | D.C. Resistance | ||||||

Al | Alloy | Total | Al | Alloy | Al | Alloy | Core | Cond. | JL/LHA2 | JL1/LHA2 | |||

| mm² | mm² | mm² | | | mm | mm | mm | mm | kg/km | KN | Ω/km | Ω/km |

25/20 | 24.30 | 18.2 | 42.5 | 4 | 3 | 2.78 | 2.78 | — | 8.34 | 116.6 | 9.23 | 0.7155 | 0.7119 |

40/30 | 38.30 | 28.7 | 67 | 4 | 3 | 3.49 | 3.49 | — | 10.5 | 183.7 | 14.36 | 0.454 | 0.4517 |

60/45 | 60.80 | 45.6 | 106 | 4 | 3 | 4.4 | 4.4 | — | 13.2 | 292 | 22.52 | 0.2856 | 0.2842 |

80/50 | 83.10 | 48.5 | 132 | 12 | 7 | 2.97 | 2.97 | 8.91 | 14.9 | 362.4 | 27.72 | 0.2298 | 0.2286 |

105/60 | 106.00 | 62.1 | 168 | 12 | 7 | 3.36 | 3.36 | 10.1 | 16.8 | 463.8 | 34.95 | 0.1796 | 0.1786 |

130/140 | 132.00 | 139 | 270 | 18 | 19 | 3.05 | 3.05 | 15.3 | 21.4 | 744.3 | 60.6 | 0.1142 | 0.1137 |

135/80 | 134.00 | 78.1 | 212 | 12 | 7 | 3.77 | 3.77 | 11.3 | 18.9 | 583.9 | 43.33 | 0.1426 | 0.1419 |

135/140 | 134.00 | 142 | 276 | 18 | 19 | 3.08 | 3.08 | 15.4 | 21.6 | 760.2 | 61.8 | 0.1122 | 0.1117 |

135/145 | 136.00 | 143 | 279 | 18 | 19 | 3.1 | 3.1 | 15.5 | 21.7 | 770.1 | 62.61 | 0.1107 | 0.1103 |

ACAR (JL2/LHA2,JL3/LHA2) GB/T 1179 | |||||||||||||

Code Number | Calculated Area | No.of Wires | Wire Diameter | Diameter | Linear Mass | Rated Strength | D.C. Resistance | ||||||

Al | Alloy | Total | Al | Alloy | Al | Alloy | Core | Cond. | JL/LHA2 | JL1/LHA2 | |||

| mm² | mm² | mm² | | | mm | mm | mm | mm | kg/km | KN | Ω/km | Ω/km |

25/20 | 24.30 | 18.2 | 42.5 | 4 | 3 | 2.78 | 2.78 | — | 8.34 | 116.6 | 9.23 | 0.7084 | 0.705 |

40/30 | 38.30 | 28.7 | 67 | 4 | 3 | 3.49 | 3.49 | — | 10.5 | 183.7 | 14.36 | 0.4495 | 0.4473 |

60/45 | 60.80 | 45.6 | 106 | 4 | 3 | 4.4 | 4.4 | — | 13.2 | 292 | 22.52 | 0.2828 | 0.2814 |

80/50 | 83.10 | 48.5 | 132 | 12 | 7 | 2.97 | 2.97 | 8.91 | 14.9 | 362.4 | 27.72 | 0.2274 | 0.2262 |

105/60 | 106.00 | 62.1 | 168 | 12 | 7 | 3.36 | 3.36 | 10.1 | 16.8 | 463.8 | 34.95 | 0.1777 | 0.1767 |

130/140 | 132.00 | 139 | 270 | 18 | 19 | 3.05 | 3.05 | 15.3 | 21.4 | 744.3 | 60.6 | 0.1133 | 0.1128 |

135/145 | 136.00 | 143 | 279 | 18 | 19 | 3.1 | 3.1 | 15.5 | 21.7 | 770.1 | 62.61 | 0.1098 | 0.1093 |

Application

ACAR conductors are extensively utilized in overhead power transmission and distribution lines, particularly suitable for:

Long-Span Applications: Where robust mechanical strength is required to bridge significant distances between towers.

Regions with High Wind or Ice Loading: Capable of withstanding substantial environmental stresses.

High-Efficiency Transmission: Offering improved current carrying capacity for efficient power transfer.

Both High-Voltage (HV) and Medium-Voltage (MV) Lines: Providing reliable performance across different voltage levels.

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products