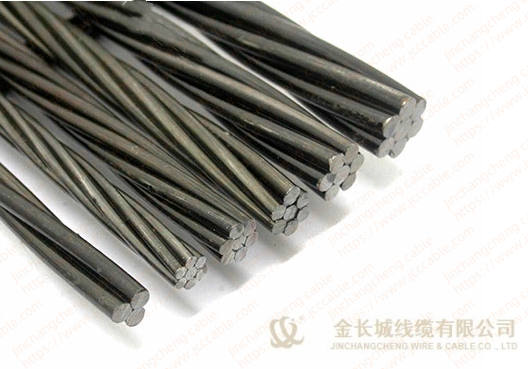

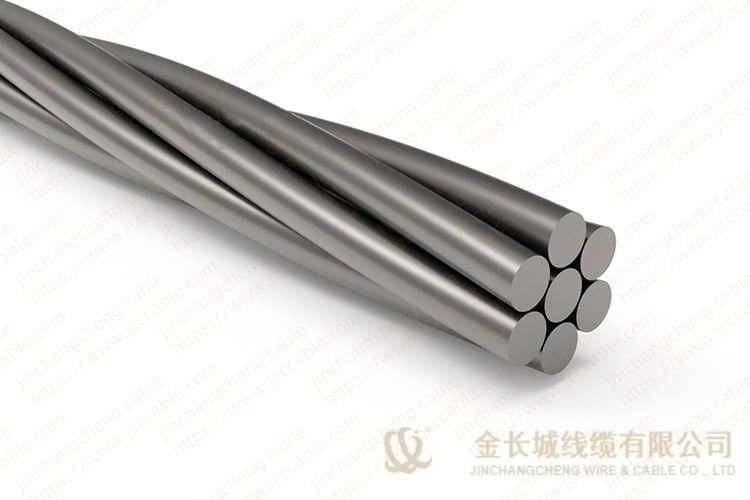

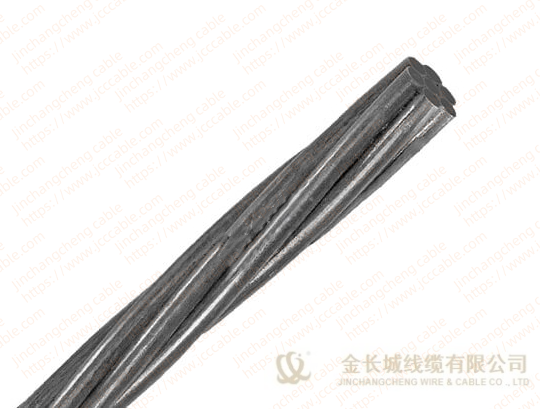

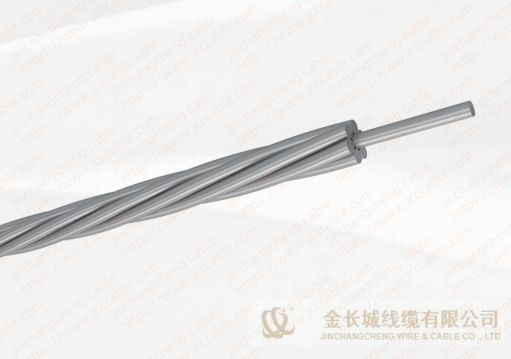

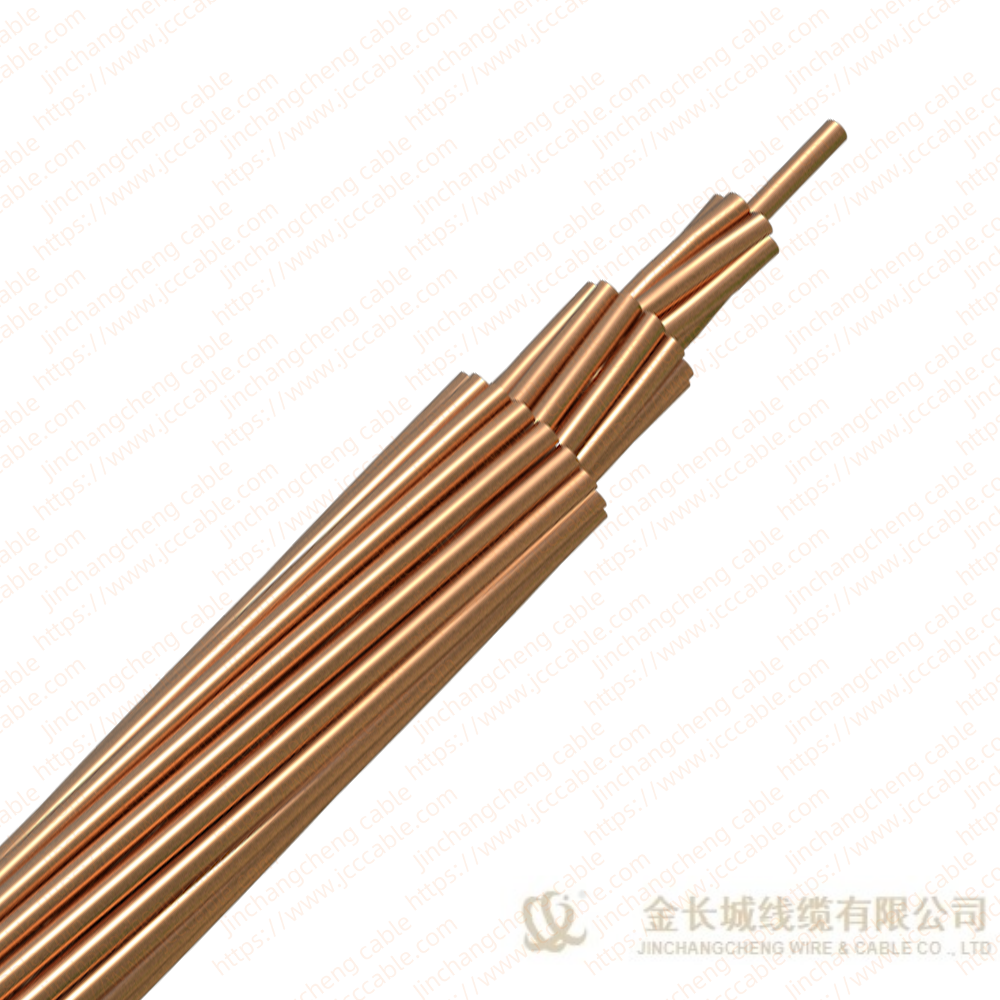

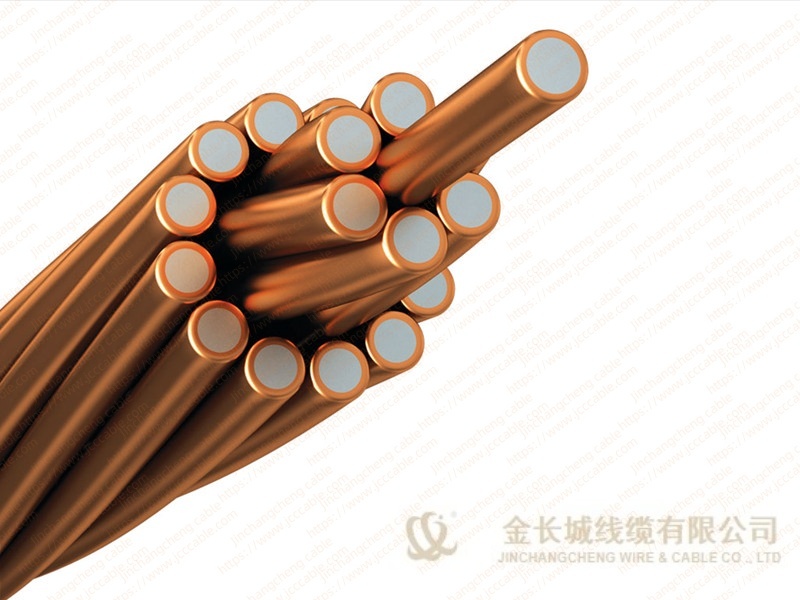

GSW-Galvanized Steel Wire Conductor

Key words:

Classification:

Product Description

Galvanized steel strand wire can be used as ground wire of overhead line, but also can be used as structural cable, supporting cable, block cable and cable reinforcement core. The galvanised stranded wire is made of wire twisted together. There are mainly ASTM standards, BS standards, IEC standards and other production standards. It is widely used in energy, construction, bridge, water conservancy and geotechnical engineering, and galvanized steel wire wholesale is also available.

Standard

IEC 61089 Zinc coated steel wires-Conductor for overhead line

GB/T 1179 Round Wire Concentric Lay Overhead Electrical Stranded Conductors

Key Features

Corrosion Resistance

The zinc coating applied through the galvanization process enhances the steel's resistance to atmospheric corrosion, making it suitable for long-term outdoor use.

High Mechanical Strength

GSW conductors offer excellent tensile strength and are capable of bearing significant mechanical loads, suitable for structural and load-bearing functions.

Cost-Effective & Durable

The simplicity of production and durability of galvanized steel make it a reliable and economical choice for mass applications.

Reliable Performance

Engineered for consistency and long service life in both standard and high-stress environments.

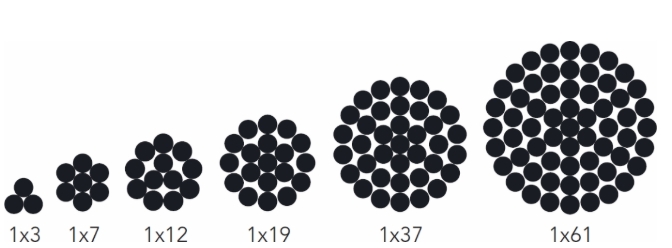

Product structure and parameter

GSW GB/T 1179

Code | Area | Number of | Diameter | Linear Mass | Rated strength | DC resistance | |||||

Wire | Cond. | JG1A | JG2A | JG3A | JG4A | JG5A | |||||

10 | 10.8 | 7 | 1.40 | 4.20 | 84.8 | 14.44 | 15.62 | 17.46 | 20.15 | 21.12 | 17.9754 |

15 | 17.8 | 7 | 1.80 | 5.40 | 140.1 | 23.87 | 25.83 | 28.86 | 33.31 | 34.91 | 10.8740 |

20 | 22.0 | 7 | 2.00 | 6.00 | 173.0 | 29.47 | 31.89 | 35.63 | 41.12 | 43.10 | 8.8079 |

25 | 26.6 | 7 | 2.20 | 6.60 | 209.3 | 35.66 | 38.58 | 43.11 | 49.76 | 52.15 | 7.2793 |

35 | 37.2 | 7 | 2.60 | 7.80 | 292.4 | 48.69 | 52.40 | 59.09 | 67.64 | 70.99 | 5.2118 |

40 | 38.2 | 19 | 1.60 | 8.00 | 301.9 | 51.19 | 55.39 | 61.89 | 71.44 | 74.88 | 5.0939 |

50 | 49.5 | 7 | 3.00 | 9.00 | 389.2 | 64.82 | 69.77 | 78.67 | 90.05 | 94.51 | 3.9146 |

50 | 48.3 | 19 | 1.80 | 9.00 | 382.1 | 64.79 | 70.11 | 78.33 | 90.41 | 94.76 | 4.0248 |

55 | 56.3 | 7 | 3.20 | 9.60 | 442.9 | 72.62 | 79.38 | 87.26 | 99.65 | 105.3 | 3.4406 |

60 | 59.7 | 19 | 2.00 | 10.0 | 471.7 | 79.98 | 86.55 | 96.70 | 111.6 | 117.0 | 3.2601 |

65 | 67.3 | 7 | 3.50 | 10.5 | 529.8 | 86.88 | 94.96 | 104.4 | 119.2 | 125.9 | 2.8761 |

70 | 72.2 | 19 | 2.20 | 11.0 | 570.8 | 96.78 | 104.73 | 117.00 | 135.1 | 141.6 | 2.6943 |

75 | 74.4 | 37 | 1.60 | 11.2 | 589.4 | 99.7 | 107.9 | 120.5 | 139.1 | 145.8 | 2.6225 |

80 | 79.4 | 7 | 3.80 | 11.4 | 624.5 | 102.4 | 109.6 | 120.7 | 136.5 | 144.5 | 2.4399 |

80 | 78.9 | 19 | 2.30 | 11.5 | 623.9 | 103.4 | 111.3 | 125.5 | 143.7 | 150.8 | 2.4651 |

90 | 88.0 | 7 | 4.00 | 12.0 | 692.0 | 113.5 | 121.4 | 133.7 | 151.3 | 160.1 | 2.2020 |

95 | 94.8 | 19 | 2.52 | 12.6 | 748.9 | 124.14 | 133.62 | 150.68 | 172.5 | 181.0 | 2.0535 |

100 | 101 | 19 | 2.60 | 13.0 | 797.2 | 132.1 | 142.2 | 160.4 | 183.6 | 192.7 | 1.9291 |

115 | 116 | 37 | 2.00 | 14.0 | 921.0 | 155.8 | 168.5 | 188.3 | 217.4 | 227.8 | 1.6784 |

125 | 125 | 19 | 2.90 | 14.5 | 991.8 | 164.4 | 177.0 | 199.5 | 228.4 | 239.7 | 1.5506 |

150 | 153 | 19 | 3.20 | 16.0 | 1207.6 | 197.1 | 215.5 | 236.9 | 270.5 | 285.7 | 1.2735 |

465 | 465 | 37 | 4.00 | 28.0 | 3683.9 | 599.8 | 641.6 | 706.7 | 799.7 | 846.2 | 0.4196 |

GSW IEC 61089

Code No. | Section Area | No./Dia of Wire | Approx. Overall Diameter | Approx. Weight | Breaking Load | DC Resistance at 20°C Max. | |||

S1A | S1B | S2A | S3A | ||||||

| mm² | No./mm | mm | kg/km | kN | kN | kN | kN | Ohm/km |

4 | 27.1 | 7/2.22 | 6.66 | 213.3 | 36.3 | 33.6 | 39.3 | 43.9 | 7.1445 |

6.3 | 42.7 | 7/2.79 | 8.36 | 335.9 | 55.9 | 51.7 | 60.2 | 67.9 | 4.5362 |

10 | 67.8 | 7/3.51 | 10.53 | 553.2 | 87.4 | 80.7 | 93.5 | 103.0 | 2.8578 |

12.5 | 84.7 | 7/3.93 | 11.78 | 666.5 | 109.3 | 100.8 | 116.9 | 128.8 | 2.2862 |

16 | 108.4 | 7/4.44 | 13.32 | 853.1 | 139.9 | 129.0 | 199.7 | 164.8 | 1.7861 |

16 | 108.4 | 19/2.70 | 13.48 | 857.0 | 142.1 | 131.2 | 152.9 | 172.4 | 1.7944 |

25 | 169.4 | 19/3.37 | 16.85 | 1339.1 | 218.6 | 201.6 | 238.9 | 262.6 | 1.1484 |

40 | 271.1 | 19/4.26 | 21.31 | 2141.6 | 349.7 | 322.6 | 374.1 | 412.1 | 0.7177 |

40 | 271.1 | 37/3.05 | 21.38 | 2148.1 | 349.7 | 322.6 | 382.3 | 420.2 | 0.7196 |

63 | 427.0 | 37/3.83 | 26.83 | 3383.2 | 550.8 | 508.1 | 589.3 | 649.0 | 0.4569 |

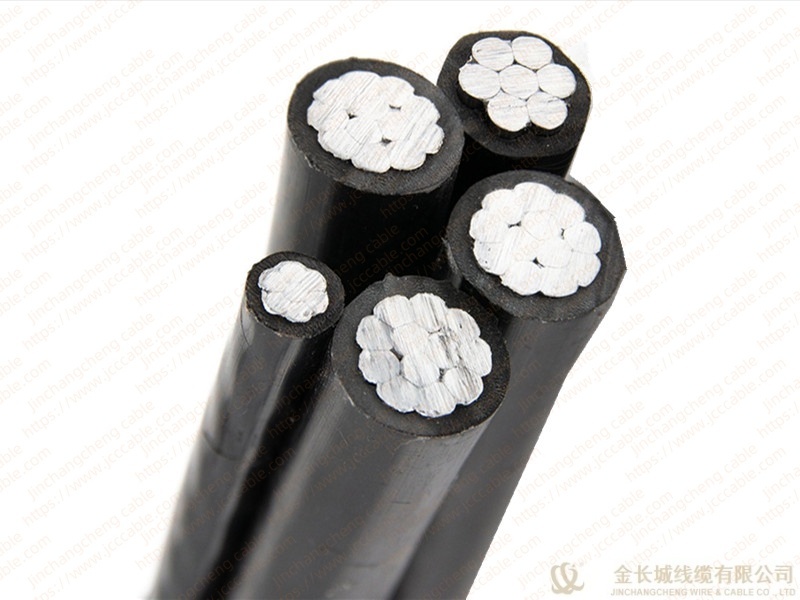

Application

GSW conductors are used across various utility and structural applications, including:

Earth Wire (Ground Wire) in overhead power lines

Stay Wire for supporting utility poles

Messenger Wire for telecom and fiber optic systems

Core Wire in ACSR conductors

Structural Reinforcement in fences and towers

Guy Wires for antenna or pole support systems

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products