VLV type 0.6/1KV PVC Insulated Power Cable

Key words:

Classification:

Product Description

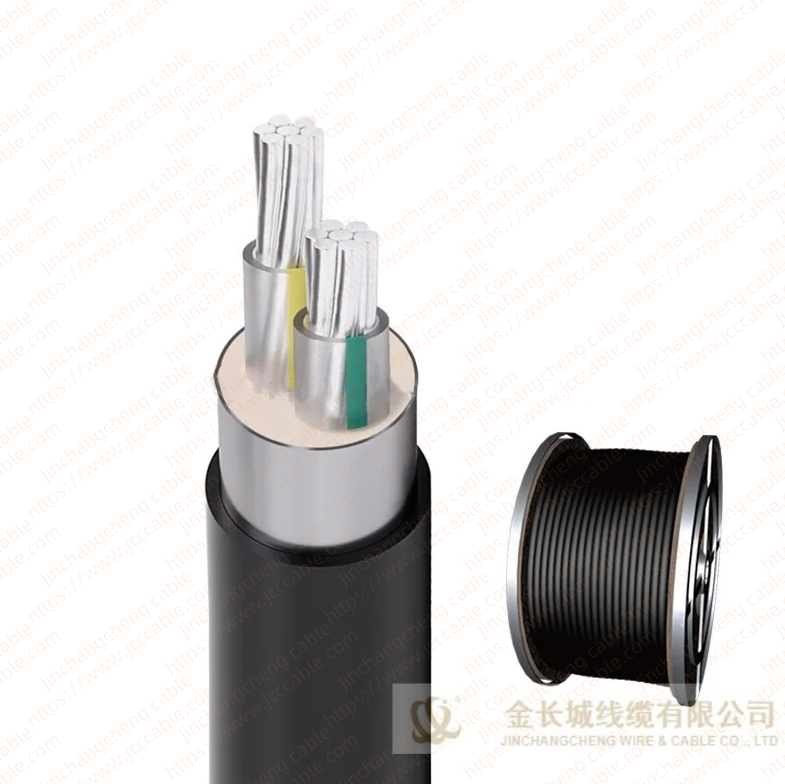

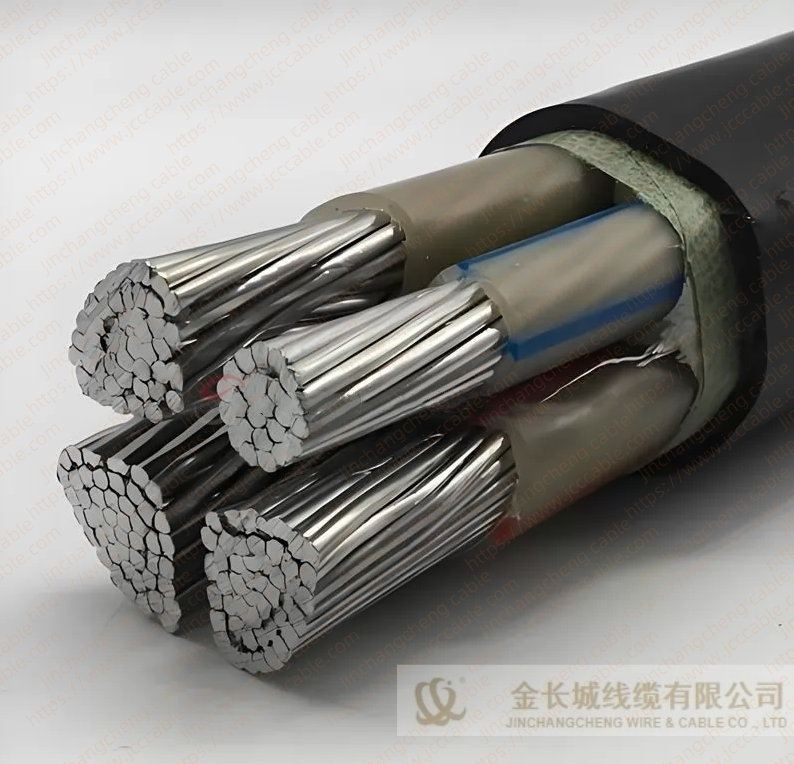

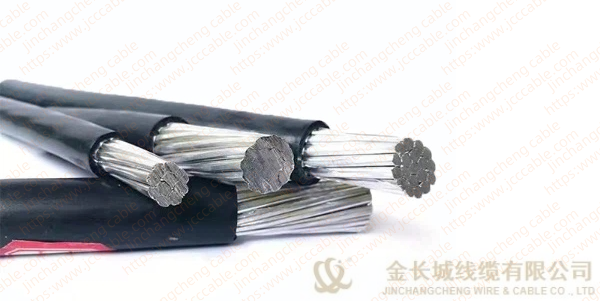

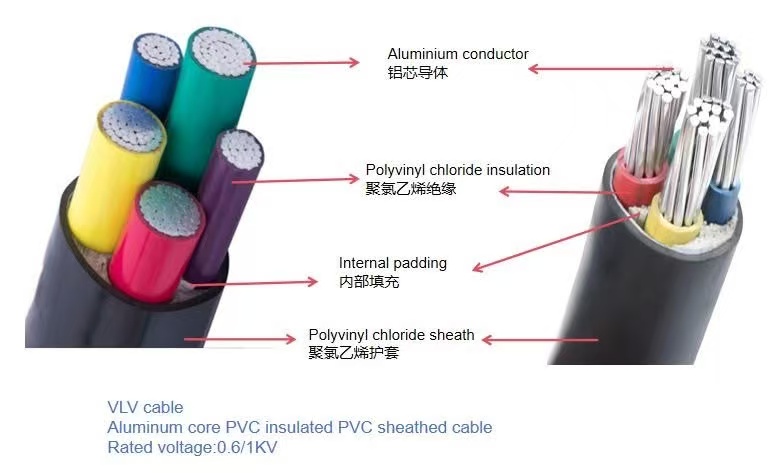

Low Voltage(0.6/1KV) Power Cable-VLV

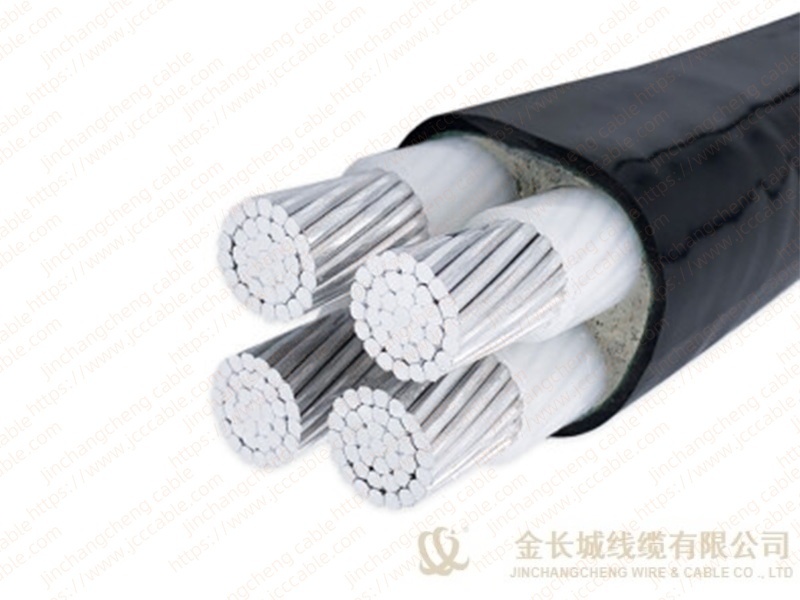

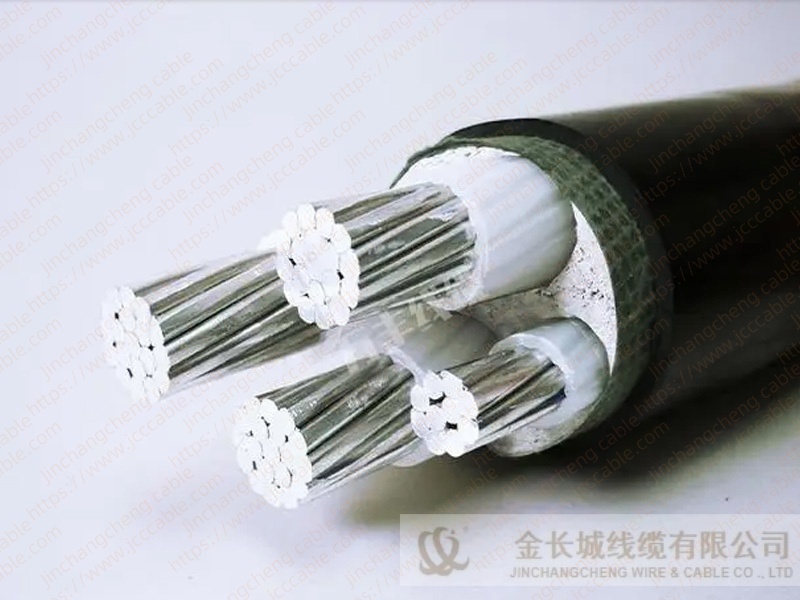

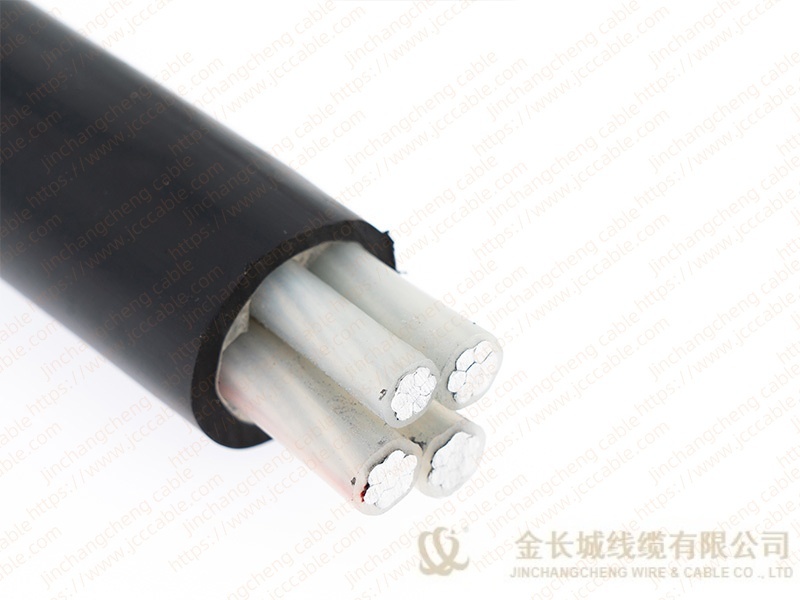

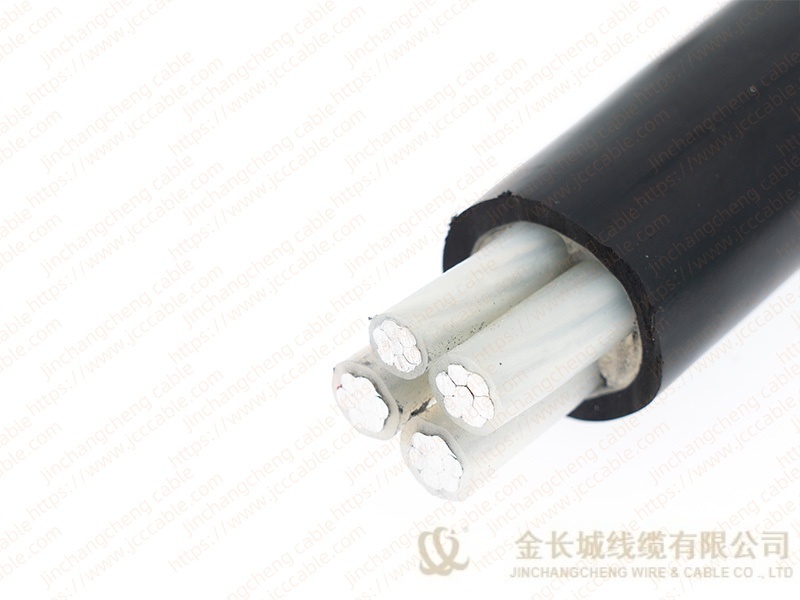

Aluminum Core PVC Insulated PVC Sheathed Power Cable is a high-performance power cable designed to provide safe and reliable power transmission in a variety of environments. The cable uses a lightweight aluminum core as conductor combined with PVC insulation and sheath materials, suitable for a variety of industrial and construction applications.

Standard

IEC 60228 Conductors of Insulate Cables

IEC 60502-1 Power Cables with Extruded Insulation and Their Accessories for Rated Voltages from 1kV(Um=1.2kV) up to 30kV(Um=36kV) - Part 1: Cables for Rated Voltages of 1kV (Um=1.2kV) and 3kV(Um=3.6kV)

Advantage:

Reduce installation costs: Lightweight design reduces transportation and installation costs, suitable for large projects.

Strong durability: The combination of PVC sheath and aluminum core makes the cable have excellent wear resistance, which can be used reliably for a long time in both indoor and outdoor environments.

Safety guarantee: Excellent insulation performance and flame-retardant PVC material provide safety guarantee for various electrical installations.

Environmentally friendly choice: Aluminum is easy to recycle and is suitable for environmentally conscious construction and power distribution projects.

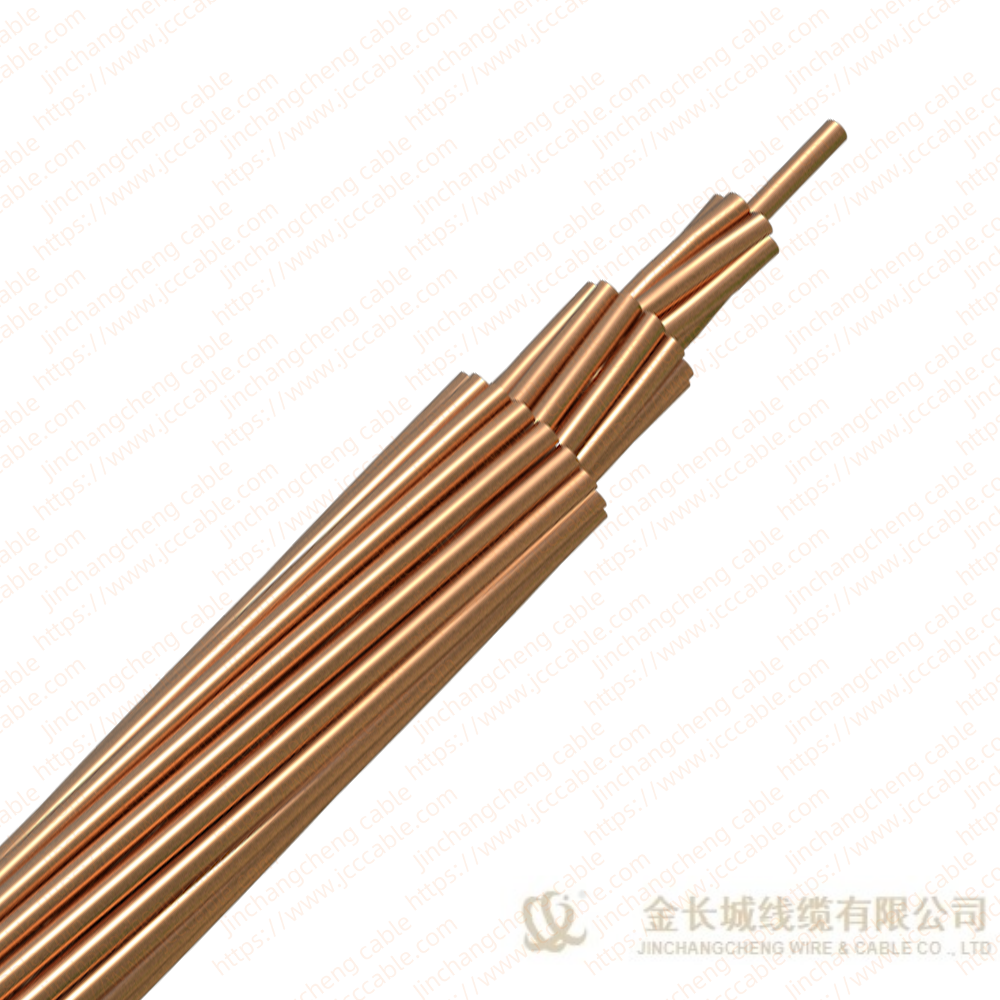

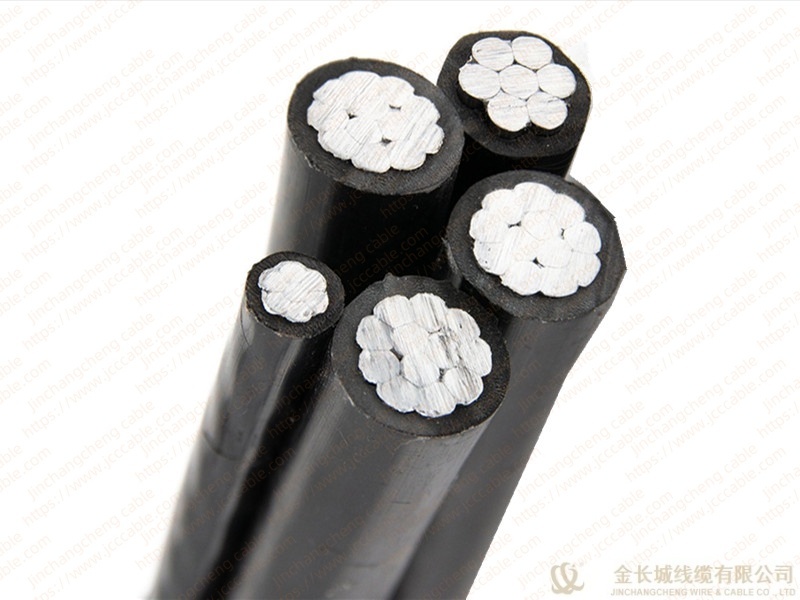

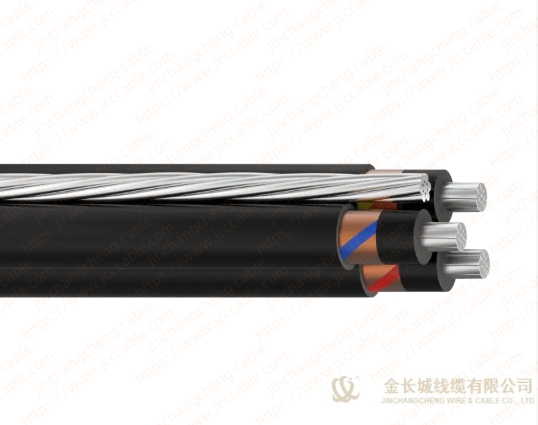

Construction

● Conductor: Aluminum, class 1 or class 2, solid or stranded, circular or circular compacted conductors

● Insulation: Polyvinyl chloride PVC

● Outer sheath: Polyvinyl chloride PVC

Product structure and parameter

No. of Cores and Nominal Cross Section | Min. Number of Wires | Nominal Insulation Thickness | Nominal | Approx. | Approx. Weight | Max. D.C. Resistance of Conductor |

No. × mm² | No. | mm | mm | mm | kg/km | Ω/km |

1×2.5 | 1 | 0.8 | 1.4 | 6.2 | 46 | 12.1 |

1×4 | 1 | 1.0 | 1.4 | 7.0 | 61 | 7.41 |

1×6 | 1 | 1.0 | 1.4 | 7.5 | 73 | 4.61 |

1×10 | 6 | 1.0 | 1.4 | 8.8 | 93 | 3.08 |

1×16 | 6 | 1.0 | 1.4 | 9.6 | 120 | 1.91 |

1×25 | 6 | 1.2 | 1.4 | 11.2 | 167 | 1.20 |

1×35 | 6 | 1.2 | 1.4 | 12.2 | 205 | 0.868 |

1×50 | 6 | 1.4 | 1.4 | 13.9 | 263 | 0.641 |

1×70 | 12 | 1.4 | 1.5 | 15.6 | 340 | 0.443 |

1×95 | 15 | 1.6 | 1.5 | 17.8 | 456 | 0.320 |

1×120 | 15 | 1.6 | 1.6 | 19.4 | 537 | 0.253 |

1×150 | 15 | 1.8 | 1.6 | 21.1 | 660 | 0.206 |

1×185 | 30 | 2.0 | 1.7 | 23.4 | 814 | 0.164 |

1×240 | 30 | 2.2 | 1.8 | 26.3 | 1043 | 0.125 |

1×300 | 30 | 2.4 | 1.9 | 29.1 | 1284 | 0.100 |

1×400 | 53 | 2.6 | 2.0 | 32.4 | 1612 | 0.0778 |

1×500 | 53 | 2.8 | 2.1 | 36.1 | 2007 | 0.0605 |

1×630 | 53 | 2.8 | 2.2 | 40.0 | 2488 | 0.0469 |

Widely Use:

Building power distribution: residential, commercial, industrial buildings.

Industrial facilities: factories, mines and other industrial environments.

Power transmission: substations, distribution networks.

Infrastructure: roads, bridges, tunnels, etc.

Mechanical equipment: various motors, pumps, fans and other mechanical equipment.

Usage Characteristics

Maximum operating temperature of conductor: 70℃

Maximum short-circuit temperature of conductor: 160℃, with a maximum duration of 5 seconds.

Installation and laying temperature: The minimum installation and laying temperature shall not be lower than 0℃.

Ambient laying temperature: When laid in air, the ambient temperature should be 40℃, and when laid in soil, the ambient temperature should be 25℃

Minimum Bending Radius:

Single-core cable: 20(D+d) ±5%

Multi-core cable: 15(D+d) ±5%

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products