Low Smoke Zero Halogen Flame Retardant and Fire Resistant Power Cable

Key words:

Classification:

Product Description

LSZH cable known as Low Smoke Zero Halogen cable / LFH (Limited Fire Hazard) cables are made of insulation materials that emit limited or low smoke and non toxic halogens when exposed to high temperature or fire. Low smoke cable and halogen free cables often used in hazardous environments and poorly ventilated areas.

Application

High-rise buildings:In high-rise buildings, the use of low-smoke halogen-free flame-retardant cables can effectively reduce the generation of smoke and avoid the release of harmful gases, thus winning precious time for the evacuation of personnel.

Subways and transportation hubs:Transportation hubs such as subways, railway stations, and airports are crowded places. Low-smoke halogen-free flame-retardant cables can effectively curb the spread of flames in fires, reduce the release of toxic gases, and ensure the normal operation of the power system.

Hospitals and medical facilities:Low-smoke halogen-free flame-retardant cables can avoid secondary damage to patients and medical staff caused by toxic gases generated by cable combustion, and ensure the normal operation of medical equipment.

Large commercial buildings and shopping malls:The flame retardant and low-smoke properties of low-smoke halogen-free flame-retardant cables can not only effectively prevent the spread of fires, but also reduce the release of harmful smoke, providing sufficient evacuation time for people in shopping malls.

Industry and mining areas:Low-smoke halogen-free flame-retardant cables can effectively prevent fires caused by power equipment failures, especially in closed environments such as underground mining areas, effectively protecting the lives of miners.

Communications and data centers:Using low-smoke halogen-free flame-retardant cables can avoid fires or downtime problems caused by power cable failures and maintain long-term stable operation of equipment.

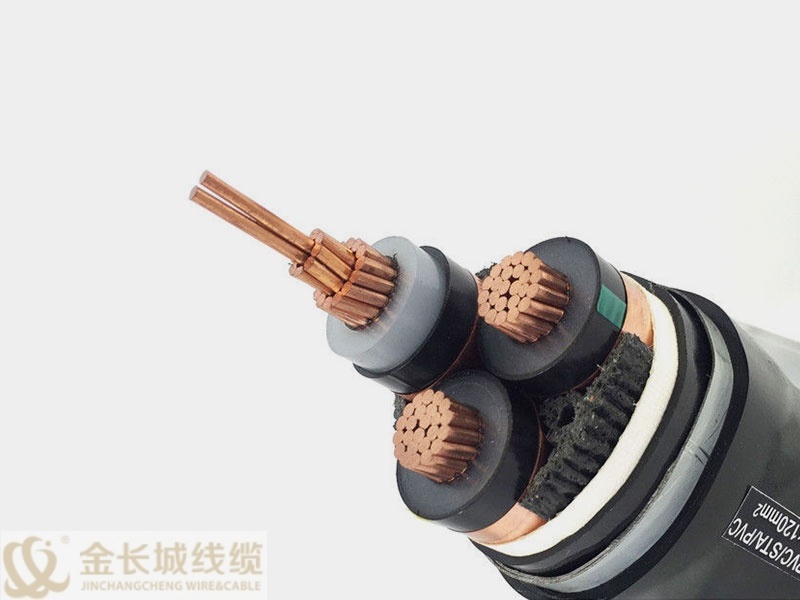

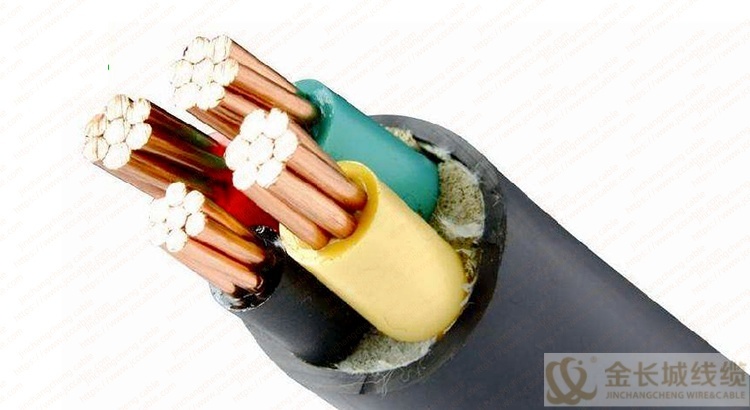

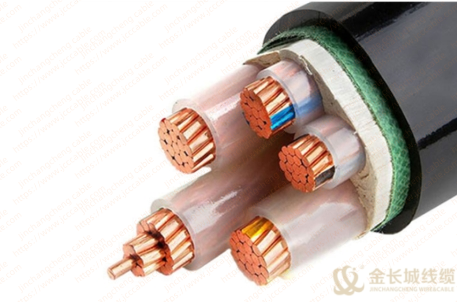

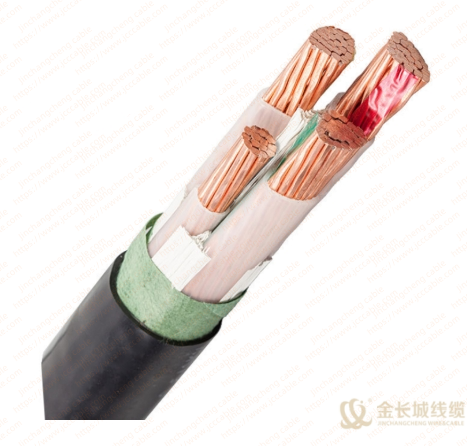

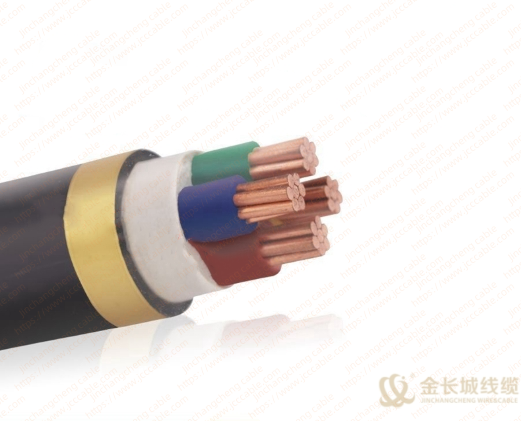

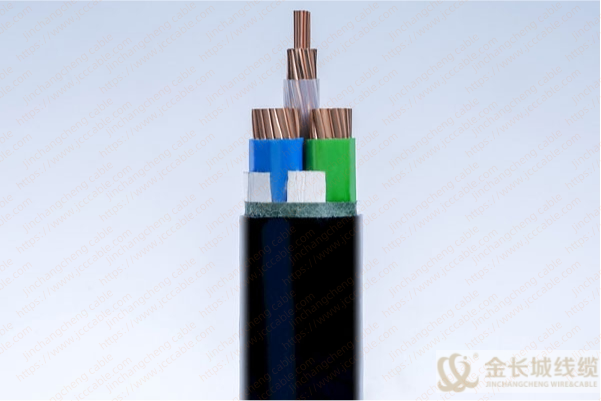

Construction

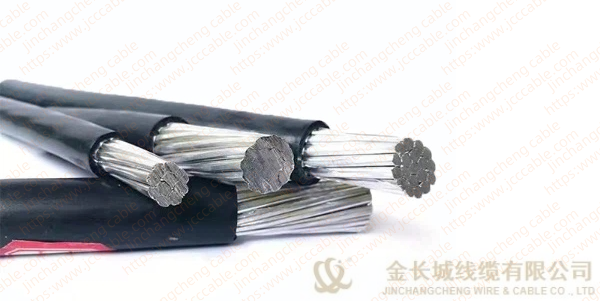

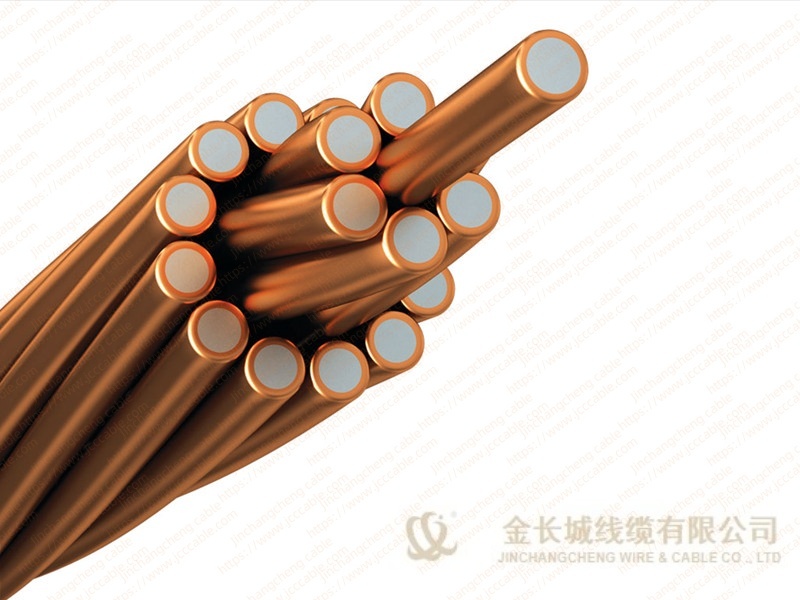

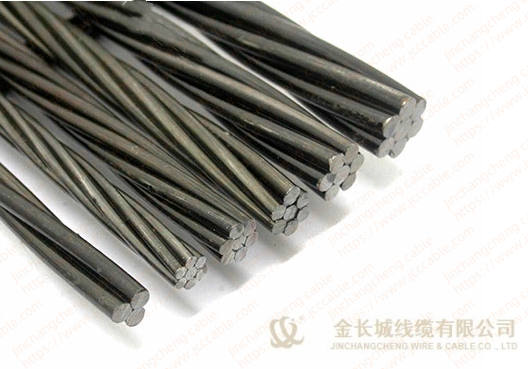

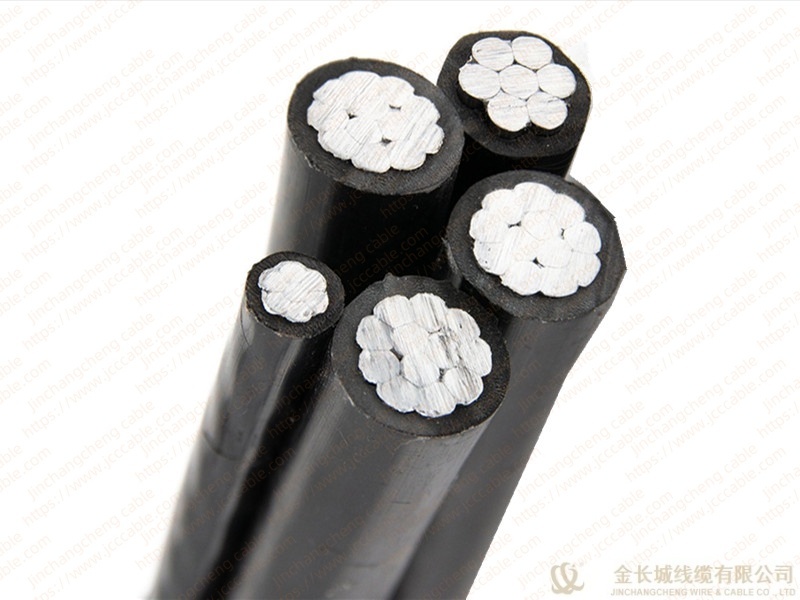

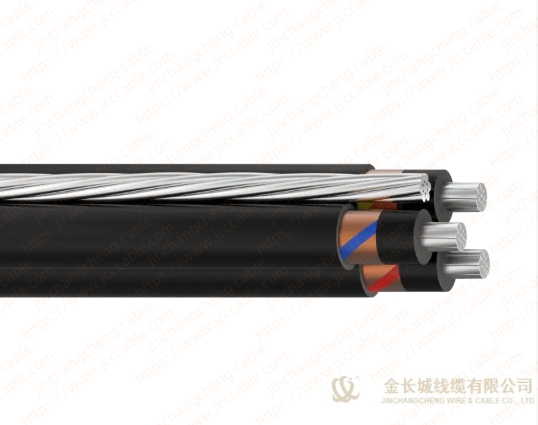

Conductor | Solid, Stranded Copper or Aluminum |

Insulation | XLPE |

Amouring | 1)Non-armoued |

Sheath | LSOH material |

Characteristics

1)Rated voltage: 0.6/1kV

1)The temperature of laying cable is not lower than 0°C.

3) Max. continuous normal operating Temperature: 90°C

4) Max. permissible temperature at short circuit (5s. at longest): 250°C.

5) Permissible bending radius:

Single core: ≥20(d+D)±5%.

Three-core:≥15(d+D)±5%

(D is the actual overall diameter of cable, and d is the actual overall diameter of conductor).

LSZH Cables intended to fulfil this type of function are often labelled as one of the following:

LSZH - Low Smoke Zero Halogen

LSOH - Low Smoke Zero Halogen

LSF - Low Smoke and Fume

OHLS - Zero Halogen Low Smoke

Both LSZH and LSF are used to limit smoke, fumes and halogen given off in fire conditions.

Safety features

Flame retardancy:The cable complies with the IEC 60332 standard. When a fire occurs, it can effectively prevent the spread of flames, avoid the expansion of fire, and ensure the safety of the power system.

Low smoke and halogen-free:The cable adopts low smoke and halogen-free materials, which complies with the IEC 60754 standard. It can reduce the release of toxic smoke in fires and greatly reduce the harm to personnel and equipment. It is especially suitable for crowded places.

Electrical safety:The cross-linked polyethylene (XLPE) insulation layer has excellent voltage breakdown resistance, which can effectively prevent electrical failures and ensure the safe operation of the power system.

Mechanical protection:The cable adopts steel belt armor, which provides it with excellent mechanical protection. Even in the case of external impact or extrusion, the cable can maintain a high stability to avoid power outages due to external damage.

Advantage:

LSZH cables, low smoke low halogen characteristics, when a fire occurs, slow the spread, low smoke density, high visibility, harmful gas emissions small, easy evacuation. Combustion gas is less corrosive, but also to avoid damage to equipment, low-halogen, halogen-free, which makes the cable materials greatly enhance the anti-aging and resistance to ultraviolet radiation and other properties, thus extending the life.

Standard

International: IEC 60502, IEC 60227 IEC 60331, IEC 61034

China: GB/T 12706-91 GB306.1-2001, GB/T18380.3-2001

Type | Description | Cores | Nominal Cross Section |

WDZN-YJY WDZBN-YJY WDZCN-YJY | Copper conductor/XLPE insulation Low Smoke Halogen Free or Zero Halogen (LSHF or LSZH) flame-retardant Power Cable | 1, 2, 3, 4, 3+1, | 1.5~800mm2 |

WDZAN-YJY23 WDZBN-YJY23 WDZCN-YJY23 | Copper conductor/XLPE insulation/Steel Tape Armored Low Smoke Halogen Free or Zero Halogen (LSHF or LSZH) flame-retardant Power Cable | 1, 2, 3, 4, 3+1, | 1.5~800mm2 |

WDZAN-YJY33 WDZBN-YJY33 WDZCN-YJY33 | Copper conductor/XLPE insulation/Steel Wire Armored Low Smoke Halogen Free or Zero Halogen (LSHF or LSZH) flame-retardant Power Cable | 1, 2, 3, 4, 3+1, | 1.5~800mm2 |

WDZAN-YJLY23 WDZBN-YJLY23 WDZCN-YJLY23 | Aluminum conductor/XLPE insulation/Steel Tape Armored Low Smoke Halogen Free or Zero Halogen (LSHF or LSZH) flame-retardant Power Cable | 1, 2, 3, 4, 3+1, | 1.5~800mm2 |

WDZAN-YJLY33 WDZBN-YJLY33 WDZCN-YJY33 | Aluminum conductor/XLPE insulation/Steel Wire Armored Low Smoke Halogen Free or Zero Halogen (LSHF or LSZH) flame-retardant Power Cable | 1, 2, 3, 4, 3+1, | 1.5~800mm2 |

Parameters

Nom. Cross-section of conductor | Insulation Thickness | Sheath | Approx. | Approx | Max. D.C. Resistance of Conductor (20°C) | Test Voltage | Current Rating | |

mm2 | mm | Thickness | O.D. | Weight | Ω/km | A.C | ||

|

| mm | mm | kg/km |

| kV/5min | In air(A) | In soil(A) |

4×1.5 | 0.7 | 1.8 | 14.4 | 241 | 12.1 | 3.5 | 20 | 27 |

4×2.5 | 0.7 | 1.8 | 15.4 | 295 | 7.41 | 3.5 | 26 | 35 |

4×4 | 0.7 | 1.8 | 16.5 | 369 | 4.61 | 3.5 | 34 | 45 |

4×6 | 0.7 | 1.8 | 17.8 | 463 | 3.08 | 3.5 | 43 | 57 |

4×10 | 0.7 | 1.8 | 20.9 | 667 | 1.83 | 3.5 | 60 | 77 |

4×16 | 0.7 | 1.8 | 23.4 | 930 | 1.15 | 3.5 | 83 | 105 |

4×25 | 0.9 | 1.8 | 27.1 | 1351 | 0.727 | 3.5 | 105 | 125 |

4×35 | 0.9 | 1.8 | 29.5 | 1772 | 0.524 | 3.5 | 125 | 155 |

4×50 | 1 | 1.9 | 38.4 | 2380 | 0.387 | 3.5 | 160 | 185 |

4×70 | 1.1 | 2 | 43.2 | 3302 | 0.268 | 3.5 | 200 | 225 |

4×95 | 1.1 | 2.2 | 47.3 | 4330 | 0.193 | 3.5 | 245 | 270 |

4×120 | 1.2 | 2.3 | 52.5 | 5374 | 0.153 | 3.5 | 285 | 310 |

4×150 | 1.4 | 2.5 | 58.3 | 6655 | 0.124 | 3.5 | 325 | 345 |

4×185 | 1.6 | 2.7 | 64.7 | 8246 | 0.0991 | 3.5 | 375 | 390 |

4×240 | 1.7 | 2.9 | 73.1 | 10569 | 0.0754 | 3.5 | 440 | 450 |

5×1.5 | 0.7 | 1.8 | 13.6 | 284 | 12.1 | 3.5 | 20 | 27 |

5×2.5 | 0.7 | 1.8 | 16.6 | 349 | 7.41 | 3.5 | 26 | 35 |

5×4 | 0.7 | 1.8 | 17.9 | 441 | 4.61 | 3.5 | 34 | 45 |

5×6 | 0.7 | 1.8 | 19.3 | 558 | 3.08 | 3.5 | 43 | 57 |

5×10 | 0.7 | 1.8 | 22.8 | 809 | 1.83 | 3.5 | 60 | 77 |

5×16 | 0.7 | 1.8 | 25.6 | 1135 | 1.15 | 3.5 | 83 | 105 |

5×25 | 0.9 | 1.8 | 29.7 | 1664 | 0.727 | 3.5 | 105 | 125 |

5×35 | 0.9 | 1.9 | 32.6 | 2194 | 0.524 | 3.5 | 125 | 155 |

5×50 | 1 | 2 | 37.3 | 3013 | 0.387 | 3.5 | 160 | 185 |

5×70 | 1.1 | 2.1 | 42.9 | 4101 | 0.268 | 3.5 | 200 | 225 |

5×95 | 1.1 | 2.2 | 48.2 | 5382 | 0.193 | 3.5 | 245 | 270 |

5×120 | 1.2 | 2.4 | 52.7 | 6685 | 0.153 | 3.5 | 285 | 310 |

5×150 | 1.4 | 2.5 | 58.5 | 8363 | 0.124 | 3.5 | 325 | 345 |

5×185 | 1.6 | 2.7 | 65.1 | 10268 | 0.0991 | 3.5 | 375 | 390 |

5×240 | 1.7 | 3.1 | 72.3 | 13167 | 0.0754 | 3.5 | 440 | 450 |

4×2.5+1×1.5 | 0.7 | 1.8 | 16.5 | 313 | 7.41 |

| 26 | 35 |

4×4+1×2.5 | 0.7 | 1.8 | 17.7 | 424 | 4.61 |

| 34 | 45 |

4×6+1×4 | 0.7 | 1.8 | 19.1 | 535 | 3.08 |

| 43 | 57 |

4×10+1×6 | 0.7 | 1.8 | 22.1 | 760 | 1.83 |

| 60 | 77 |

4×16+1×10 | 0.7 | 1.8 | 25.1 | 1071 | 1.15 |

| 83 | 105 |

4×25+1×16 | 0.7 | 1.8 | 29 | 1556 | 0.727 |

| 105 | 125 |

4×35+1×16 | 0.9 | 1.9 | 31.4 | 1976 | 0.524 |

| 125 | 155 |

4×50+1×25 | 1 | 2.1 | 36 | 2689 | 0.387 |

| 160 | 185 |

4×70+1×35 | 1.1 | 2.2 | 41.1 | 3719 | 0.268 |

| 200 | 225 |

4×95+1×50 | 1.1 | 2.4 | 46.3 | 4903 | 0.193 |

| 245 | 270 |

4×120+1×70 | 1.2 | 2.5 | 51 | 6165 | 0.153 |

| 285 | 310 |

4×150+1×70 | 1.4 | 2.7 | 55.8 | 7431 | 0.124 |

| 325 | 345 |

4×185+1×95 | 1.6 | 2.9 | 62.1 | 9192 | 0.0991 |

| 375 | 390 |

4×240+1×120 | 1.7 | 3.1 | 68.8 | 11860 | 0.0754 |

| 440 | 450 |

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products