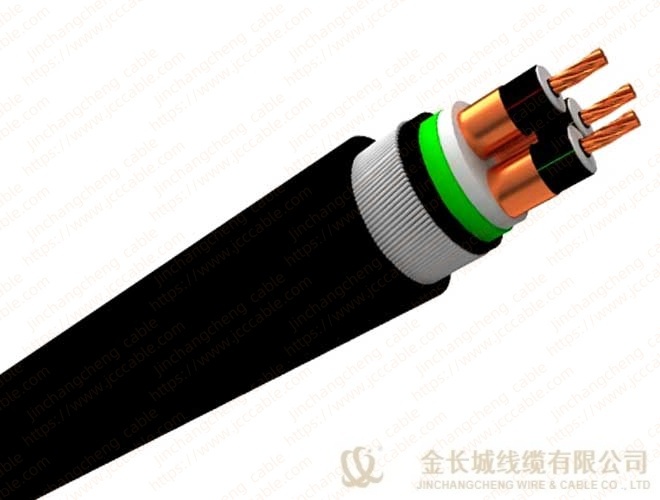

PVC Insulated Flame Retardant Mining Power Cable

Key words:

Classification:

Product Description

PVC Insulated Flame Retardant Mining Power Cable

Application:

Cables are applicable to transmit electric energy for colliery equipment with AC rated voltage up to 6kV. Coal mines are high-risk, high-intensity working environments, requiring power cables to have excellent durability, pressure resistance and stability. PVC insulated power cables for coal mines, including four models: MVV, MVV22, MVV32, MVV42 are specially designed for mine power transmission systems and can operate stably for a long time in harsh environments such as humidity, dust and mechanical shock, ensuring the safety and efficiency of mine operations.

Manufacturing standard:

MT 818.12

Service Property Parameter:

1. Max.Permitted continuous operating temperature of conductor is 70℃.

2. Upon short circuit(max duration time 5s).the Max.temperature of conductor not higher than 160℃.

3. Ambient temperature of installation not less than 0℃.

4. Preferred permissible bending radius not less than 15 times of cable diameter.

Type & Description:

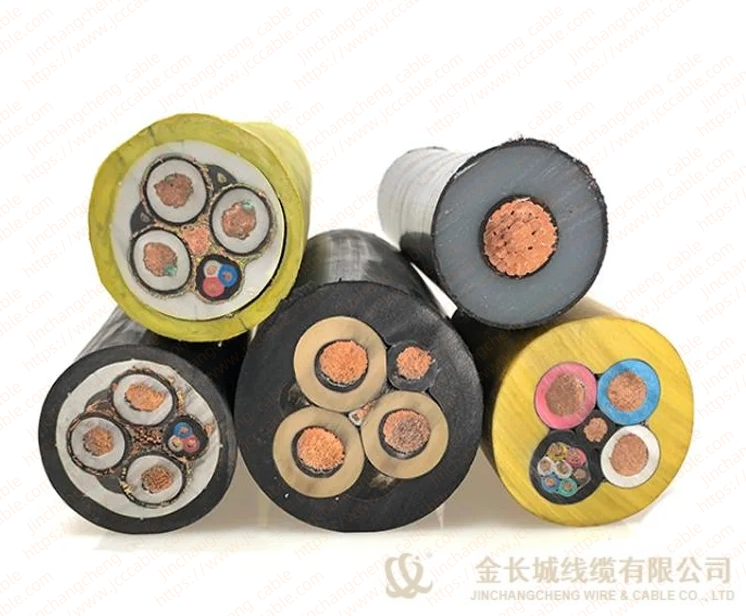

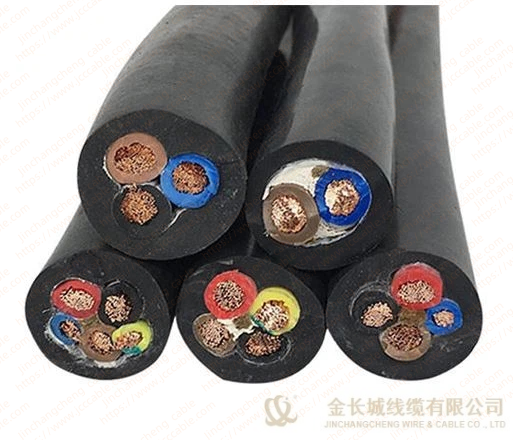

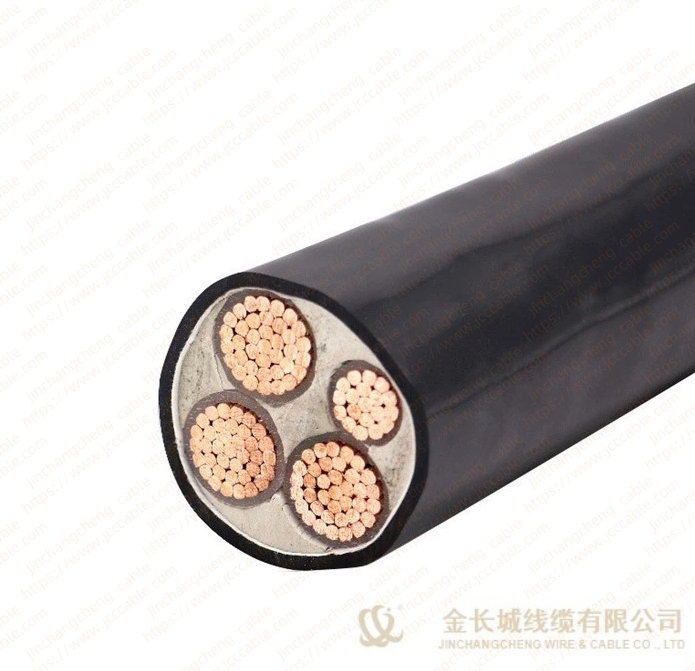

Type | Description |

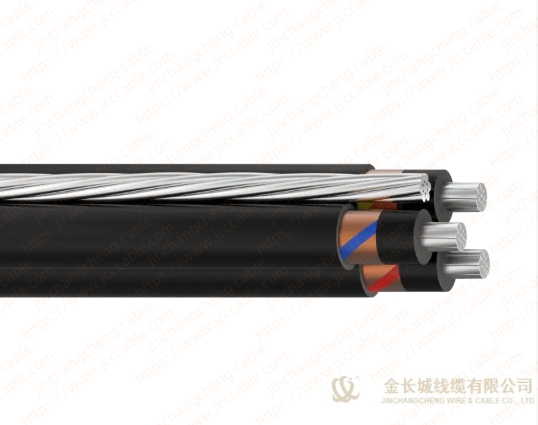

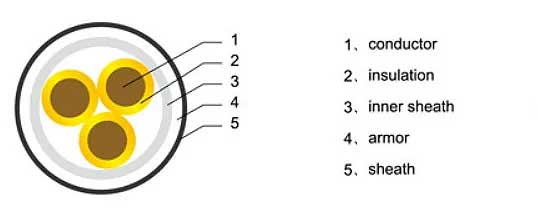

MVV | PVC insulated PVC sheathed flame retardant mining power cable |

MVV22 | PVC insulated steel tape armored PVC sheathed flame retardant mining power cable |

MVV32 | PVC insulated thin steel wire armored PVC sheathed flame retardant mining power cable |

MVV42 | PVC insulated thick steel wire armored PVC sheathed flame retardant mining power cable |

Applicable scenarios and application environments

MVV cable: widely used in coal mines, tunnels, mines and other environments, used in power transmission lines, suitable for fixed laying environments without external forces.

MVV22 cable: based on MVV, steel belt armor is added, suitable for coal mines, tunnels, mines and other environments, can withstand certain mechanical external forces, suitable for use in places with more mechanical equipment and slightly harsh environments.

MVV32 cable: with steel wire armor, suitable for deep well mining, mine bottom and other environments that need to withstand large tension and external pressure, can effectively prevent cable damage under extreme conditions such as rock squeezing and collision, and ensure stable operation of the power system.

Main Technical Indexes:

1. D.C.resistance of conductor shall comply with GB/T3956.

2. Cables with rated voltage above 3.6kV shall be applied for parital discharge test,the magnitude of the discharge at 1.5U0 shall not exceed 40pC.

3. Cables with rated voltage up to 3.6kV shall withstand 2.5U0+2kV voltage test; cables with rated voltage above 3.6kV shall with stand 2.5U +2kV voltage test; cables with rated voltage above 3.6kV shall withstand 2.5U0 voltage test.

4.Flame - retardant performance: conform to MT386.

Technical Data:

MVV Cable

Number of cores | Conductor Diameter | Conductor cross section | Insulation Thickness | Resistance | Sheath Thickness | Cable outer diameter | weight | Current |

Three cores | 1.8 | 2.5 | 0.8 | 7.41 | 1.8 | 11.8 | 187 | 29/19 |

| 2.3 | 4 | 1 | 4.61 | 1.8 | 13.7 | 265 | 38/26 |

| 2.8 | 6 | 1 | 3.08 | 1.8 | 15.7 | 380 | 47/32 |

| 3.8 | 10 | 1 | 1.83 | 1.8 | 17.6 | 514 | 65/46 |

| 4.8 | 16 | 1 | 1.15 | 1.8 | 19.8 | 728 | 84/60 |

| 6 | 25 | 1.2 | 0.727 | 1.8 | 23.6 | 1084 | 110/77 |

| 7 | 35 | 1.2 | 0.524 | 1.8 | 26.1 | 1422 | 130/95 |

| 8.3 | 50 | 1.4 | 0.387 | 1.8 | 26.5 | 1801 | 155/115 |

| 9.8 | 70 | 1.4 | 0.268 | 1.9 | 28.8 | 2415 | 195/145 |

| 11.5 | 95 | 1.6 | 0.193 | 2.1 | 33.7 | 3255 | 230/185 |

| 12.9 | 120 | 1.6 | 0.153 | 2.2 | 37.1 | 4037 | 260/210 |

| 14.5 | 150 | 1.8 | 0.124 | 2.3 | 41.9 | 5028 | 300/245 |

| 16 | 185 | 2 | 0.0991 | 2.5 | 45.9 | 6180 | 335/280 |

| 18.3 | 240 | 2.2 | 0.0754 | 2.7 | 51.7 | 7947 | 390/335 |

| 20.5 | 300 | 2.4 | 0.0601 | / | / | / | / |

MVV22 Cable

Number of cores | Conductor Diameter | Conductor cross section | Insulation Thickness | Resistance | Sheath Thickness | Strip Thickness | Cable Outer Diameter | weight | Current |

Three cores | 1.8 | 2.5 | 0.8 | 7.41 | / | / | / | / | / |

| 2.3 | 4 | 1 | 4.61 | 1.8 | 0.2×2 | 17.3 | 489 | 38/26 |

| 2.8 | 6 | 1 | 3.08 | 1.8 | 0.2×2 | 18.4 | 577 | 47/32 |

| 3.8 | 10 | 1 | 1.83 | 1.8 | 0.2×2 | 21.2 | 800 | 65/46 |

| 4.8 | 16 | 1 | 1.15 | 1.8 | 0.2×2 | 23.5 | 1050 | 84/60 |

| 6 | 25 | 1.2 | 0.727 | 1.8 | 0.2×2 | 27.2 | 1465 | 110/77 |

| 7 | 35 | 1.2 | 0.524 | 1.9 | 0.2×2 | 30.7 | 2150 | 130/95 |

| 8.3 | 50 | 1.4 | 0.387 | 2 | 0.5×2 | 31.4 | 2453 | 155/115 |

| 9.8 | 70 | 1.4 | 0.268 | 2.2 | 0.5×2 | 33.6 | 3116 | 195/145 |

| 11.5 | 95 | 1.6 | 0.193 | 2.4 | 0.5×2 | 38.2 | 4053 | 230/185 |

| 12.9 | 120 | 1.6 | 0.153 | 2.5 | 0.5×2 | 41.9 | 4930 | 260/210 |

| 14.5 | 150 | 1.8 | 0.124 | 2.6 | 0.5×2 | 47.1 | 6075 | 300/245 |

| 16 | 185 | 2 | 0.0991 | 2.8 | 0.5×2 | 50.9 | 7300 | 335/280 |

| 18.3 | 240 | 2.2 | 0.0754 | 3 | 0.5×2 | 57 | 9231 | 390/335 |

| 20.5 | 300 | 2.4 | 0.0601 | 3.2 | 0.5×2 | 61.8 | 11277 | 435/375 |

MVV32 Cable

Number of cores | Conductor Diameter | Conductor cross section | Insulation Thickness | Resistance | Sheath Thickness | Wire Diameter | Cable Outer Diameter | weight | Current |

Three cores | 1.8 | 2.5 | 0.8 | 7.41 | / | / | / | / | / |

| 2.3 | 4 | 1 | 4.61 | / | / | / | / | / |

| 2.8 | 6 | 1 | 3.08 | / | / | / | / | / |

| 3.8 | 10 | 1 | 1.83 | 1.8 | 0.8 | 23 | 1172 | 65/46 |

| 4.8 | 16 | 1 | 1.15 | 1.8 | 0.8 | 25.3 | 1457 | 84/60 |

| 6 | 25 | 1.2 | 0.727 | 1.8 | 1.6 | 29 | 1936 | 110/77 |

| 7 | 35 | 1.2 | 0.524 | 1.9 | 1.6 | 31.7 | 2359 | 130/95 |

| 8.3 | 50 | 1.4 | 0.387 | 2 | 1.6 | 36.4 | 3216 | 155/115 |

| 9.8 | 70 | 1.4 | 0.268 | 2.2 | 2 | 41.1 | 4164 | 195/145 |

| 11.5 | 95 | 1.6 | 0.193 | 2.4 | 2 | 47.4 | 5498 | 230/185 |

| 12.9 | 120 | 1.6 | 0.153 | 2.5 | 2 | 51.3 | 6836 | 260/210 |

| 14.5 | 150 | 1.8 | 0.124 | 2.6 | 2.5 | 55.9 | 8061 | 300/245 |

| 16 | 185 | 2 | 0.0991 | 2.8 | 2.5 | 61.4 | 9640 | 335/280 |

| 18.3 | 240 | 2.2 | 0.0754 | 3 | 2.5 | 68.5 | 12002 | 390/335 |

| 20.5 | 300 | 2.4 | 0.0601 | 3.2 | 2.5 | 75.2 | 14489 | 435/375 |

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products