ACSR-Aluminum Conductor Steel Reinforced

Key words:

Classification:

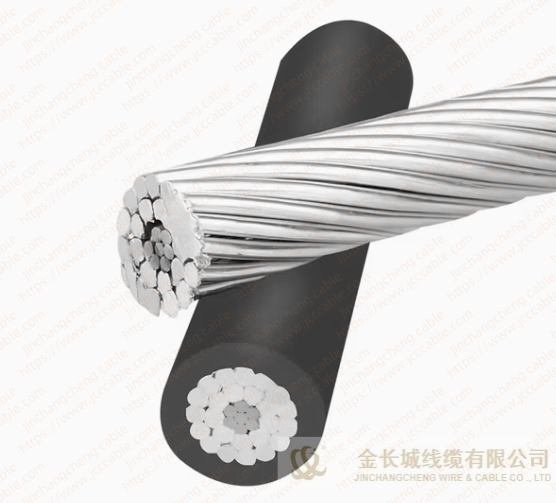

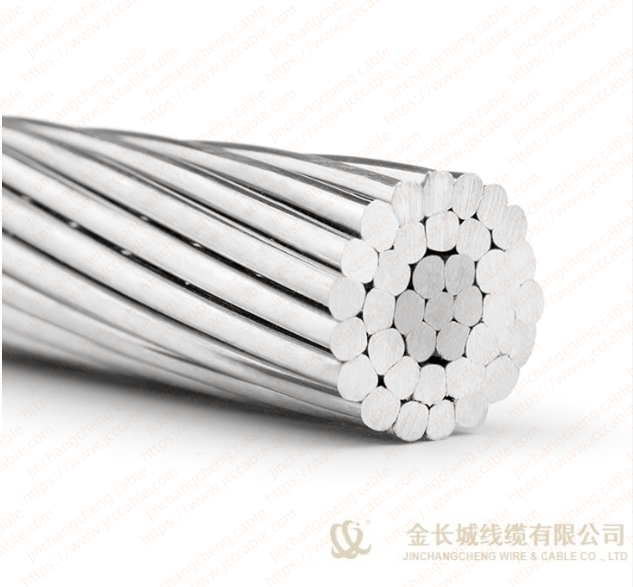

Product Description

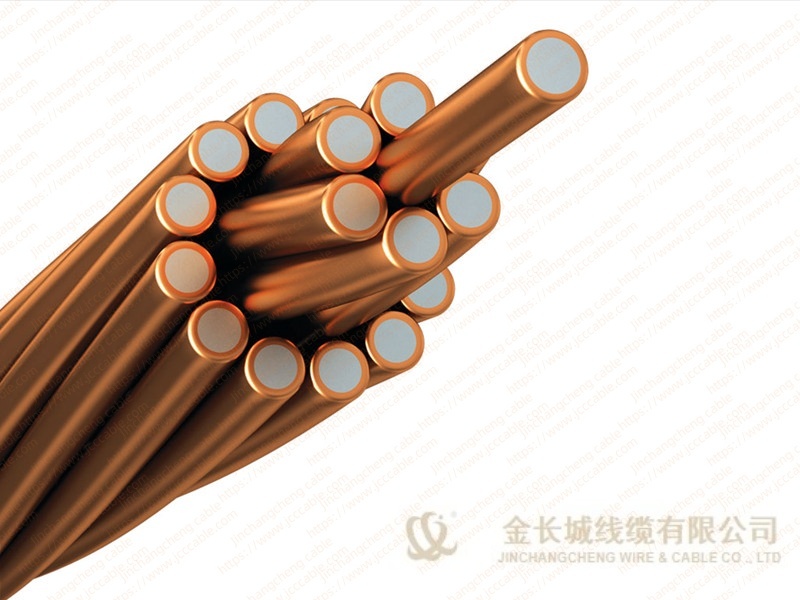

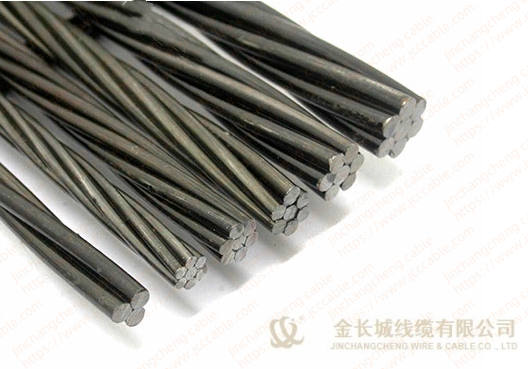

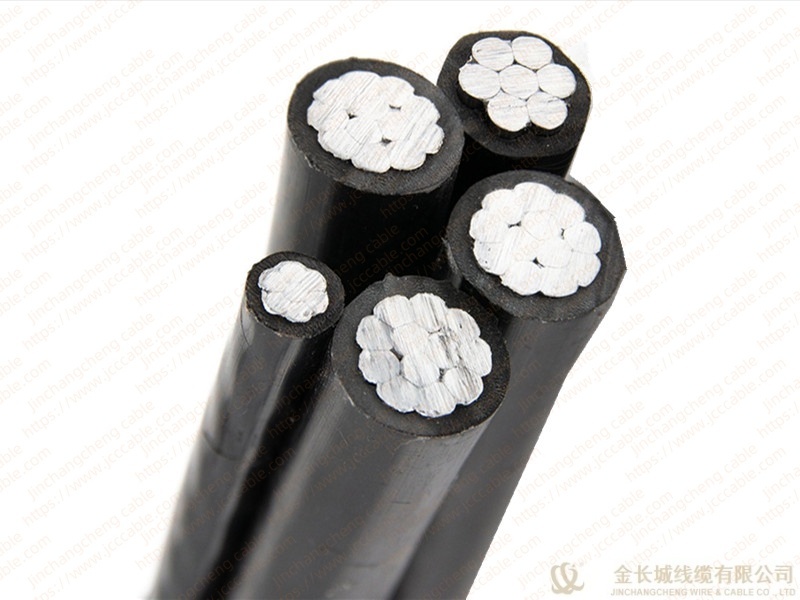

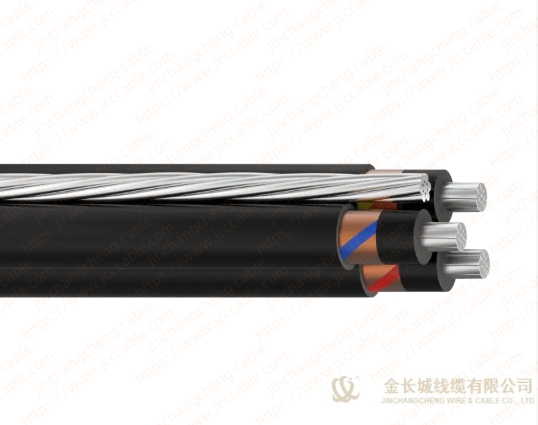

The aluminum conductor steel reinforced is made through stranding aluminum wires and steel wires, and is used as main power transmission line. Its inner part is the steel core, with the aluminum wires stranded around the steel core in a spiral manner and according to a certain rule. The steel core is used to enhance the strength of ACSR.

Standard

Our Bare conductor can meet or exceedthe item of cable international standards, such as:IEC 61089,GB/T1179

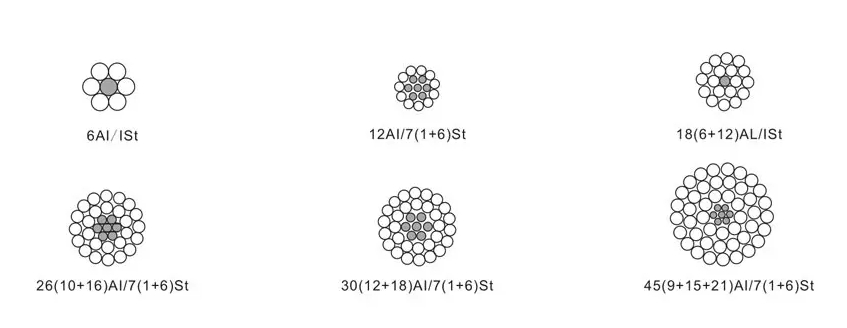

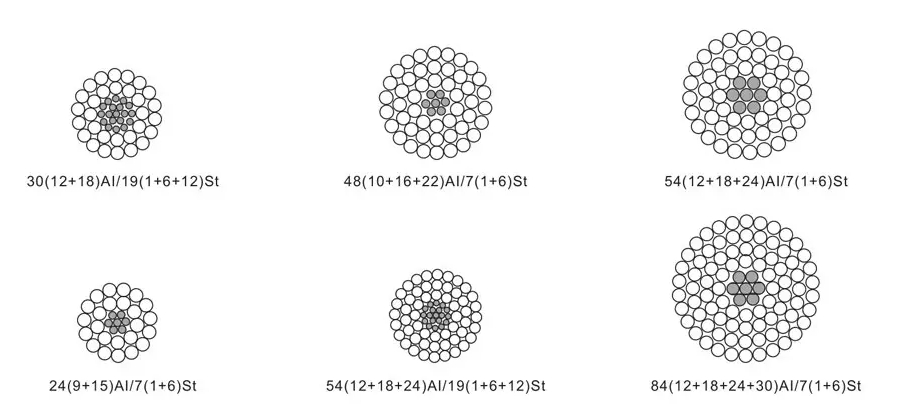

Structure

- The hard aluminum conductor used for ACSR conforms to the standard GB/T 1179-2008(equivalent to IEC 61089).

2.The zinc coated steel wire used for ACSR conforms to IEC 61089.

3.Production can be arranged according to customers requirements for material standard,etc.

4We can also produce products according to the Standard of BS215, ASTM B232, and DIN48204.

Feature

1.The electrical performance of ACSR is indicated in DCΩ/km (20oC).The resistivity of the hard aluminum wire for stranded wires is not greater than 28.264 nΩ. m of international standard value.

2.The rated tensile strengh of ACSR is denoted with sum of all aluminum conductorstensile strength and steels tensile strength.

3.The tensile strength of all aluminum conductors is denoted with the result of all cross sections of aluminum conductors multiplied by min.tensile strength of corresponding size specified in the standard for aluminum wire.

4.The tensile strength of all steel wire is denoted with the result of all cross sections of steel wires multiplied by the stress at 1% elongation of corresponding size specified in the standard for steel wire.

Product structure and parameter

ACSR Conductor IEC 61089

Code Number | Area | Number of wires | Wire dia. | Diameter | Linear | Rated | D.C. | |||||

| Alum | Steel | Total | | Alum | Steel | Core | Con. | | |||

| mm 2 | mm 2 | mm 2 | Al | St | mm | mm | mm | mm | kg/km | kN | Ω/km |

16 | 16 | 2.67 | 18.7 | 6 | 1 | 1.84 | 1.84 | 1.84 | 5.53 | 64.6 | 6.08 | 1.7934 |

25 | 25 | 4.17 | 29.2 | 6 | 1 | 2.3 | 2.3 | 2.3 | 6.91 | 100.9 | 9.13 | 1.1478 |

40 | 40 | 6.67 | 46.7 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.74 | 161.5 | 14.4 | 0.7174 |

63 | 63 | 10.5 | 73.5 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11 | 254.4 | 21.63 | 0.4555 |

100 | 100 | 16.7 | 117 | 6 | 1 | 4.61 | 4.61 | 4.61 | 13.8 | 403.8 | 34.33 | 0.2869 |

125 | 125 | 6.94 | 132 | 18 | 1 | 2.97 | 2.97 | 2.97 | 14.9 | 397.9 | 29.17 | 0.2304 |

125 | 125 | 20.4 | 145 | 26 | 7 | 2.47 | 1.92 | 5.77 | 15.7 | 503.9 | 45.69 | 0.231 |

160 | 160 | 8.89 | 169 | 18 | 1 | 3.36 | 3.36 | 3.36 | 16.8 | 508.3 | 36.18 | 0.18 |

160 | 160 | 26.1 | 186 | 26 | 7 | 2.8 | 2.18 | 6.53 | 17.7 | 644.9 | 57.69 | 0.1805 |

200 | 200 | 11.1 | 211 | 18 | 1 | 3.76 | 3.76 | 3.76 | 18.8 | 636.7 | 44.22 | 0.144 |

200 | 200 | 32.6 | 233 | 26 | 7 | 3.13 | 2.43 | 7.3 | 19.8 | 806.2 | 70.13 | 0.1444 |

250 | 250 | 24.6 | 275 | 22 | 7 | 3.8 | 2.11 | 6.34 | 21.6 | 880.6 | 68.72 | 0. 1154 |

250 | 250 | 40.7 | 291 | 26 | 7 | 3.5 | 2.72 | 8.16 | 22.2 | 1007.7 | 87.67 | 0.1155 |

315 | 315 | 21.8 | 337 | 45 | 7 | 2.99 | 1.99 | 5.97 | 23.9 | 1039.3 | 79.03 | 0.0917 |

315 | 315 | 51.3 | 366 | 26 | 7 | 3.93 | 3.05 | 9.16 | 24.9 | 1269.7 | 106.83 | 0.0917 |

400 | 400 | 27.7 | 428 | 45 | 7 | 3.36 | 2.24 | 6.73 | 26.9 | 1320.1 | 98.36 | 0.0722 |

400 | 400 | 51.9 | 452 | 54 | 7 | 3.07 | 3.07 | 9.21 | 27.6 | 1510.3 | 123.04 | 0.0723 |

450 | 450 | 31.1 | 481 | 45 | 7 | 3.57 | 2.38 | 7.14 | 28.5 | 1485.2 | 107. 47 | 0 0642 |

450 | 450 | 58.3 | 508 | 54 | 7 | 3.26 | 3.26 | 9.77 | 29.3 | 1699.1 | 138.42 | 0.0643 |

500 | 500 | 34.6 | 535 | 45 | 7 | 3.76 | 2.51 | 7.52 | 30.1 | 1650.2 | 119.41 | 0.0578 |

500 | 500 | 64.8 | 565 | 54 | 7 | 3.43 | 3.43 | 10.3 | 30.9 | 1887.9 | 153.8 | 0.0578 |

560 | 560 | 38.7 | 599 | 45 | 7 | 3.98 | 2.65 | 7.96 | 31.8 | 1848.2 | 133.74 | 0.0516 |

560 | 560 | 70.9 | 631 | 54 | 19 | 3.63 | 2.18 | 10.9 | 32.7 | 2103.4 | 172.59 | 0.0516 |

630 | 630 | 43.6 | 674 | 45 | 7 | 4.22 | 2.81 | 8.44 | 33.8 | 2079.2 | 150.45 | 0.0459 |

630 | 630 | 79.8 | 710 | 54 | 19 | 3.85 | 2.31 | 11.6 | 34.7 | 2366.3 | 191.77 | 0.0459 |

ACSR (JL/G1A)

Code | Steel Ratio | Calculated Area | Number of Wires | Wire Diameter | Diameter | Linear | Rated Strength | DC. Resistance at 20℃ | |||||

Al | St | Total | Al | St | Al | St | Steel | Cond. | |||||

% | mm2 | mm2 | mm2 | | | mm | mm | mm | mm | kg/km | kN | Ω/km | |

10/2 | 16.7 | 10.6 | 1.78 | 12.4 | 6 | 1 | 1.50 | 1.50 | 1.50 | 4.50 | 42.8 | 4.14 | 2.7062 |

16/3 | 16.7 | 16.1 | 2.69 | 18.8 | 6 | 1 | 1.85 | 1.85 | 1.85 | 5.55 | 65.2 | 6.13 | 1.7791 |

25/4 | 16.7 | 24.9 | 4.15 | 29.1 | 6 | 1 | 2.30 | 2.30 | 2.30 | 6.90 | 100.7 | 9.10 | 1.1510 |

35/6 | 16.7 | 34.9 | 5.81 | 40.7 | 6 | 1 | 2.72 | 2.72 | 2.72 | 8.16 | 140.9 | 12.55 | 0.8230 |

40/6 | 16.7 | 39.9 | 6.65 | 46.6 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.73 | 161.2 | 14.37 | 0.7190 |

50/8 | 16.7 | 48.3 | 8.04 | 56.3 | 6 | 1 | 3.20 | 3.20 | 3.20 | 9.60 | 195.0 | 16.81 | 0.5946 |

50/30 | 58.3 | 50.7 | 29.6 | 80.3 | 12 | 7 | 2.32 | 2.32 | 6.96 | 11.6 | 371.3 | 42.61 | 0.5693 |

65/10 | 16.7 | 63.1 | 10.5 | 73.6 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11.0 | 255.1 | 21.67 | 0.4546 |

70/10 | 16.7 | 68.0 | 11.3 | 79.3 | 6 | 1 | 3.80 | 3.80 | 3.80 | 11.4 | 275.0 | 23.36 | 0.4217 |

70/40 | 58.3 | 69.7 | 40.7 | 110 | 12 | 7 | 2.72 | 2.72 | 8.16 | 13.6 | 510.4 | 58.22 | 0.4141 |

95/15 | 16.2 | 94.4 | 15.3 | 110 | 26 | 7 | 2.15 | 1.67 | 5.01 | 13.6 | 380.5 | 34.93 | 0.3059 |

95/20 | 19.8 | 95.1 | 18.8 | 114 | 7 | 7 | 4.16 | 1.85 | 5.55 | 13.9 | 408.5 | 37.24 | 0.3020 |

95/55 | 58.3 | 96.5 | 56.3 | 153 | 12 | 7 | 3.20 | 3.20 | 9.60 | 16.0 | 706.4 | 77.85 | 0.2992 |

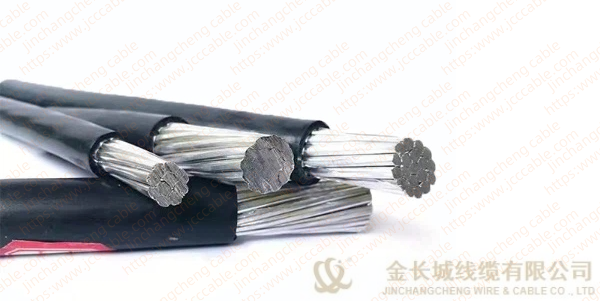

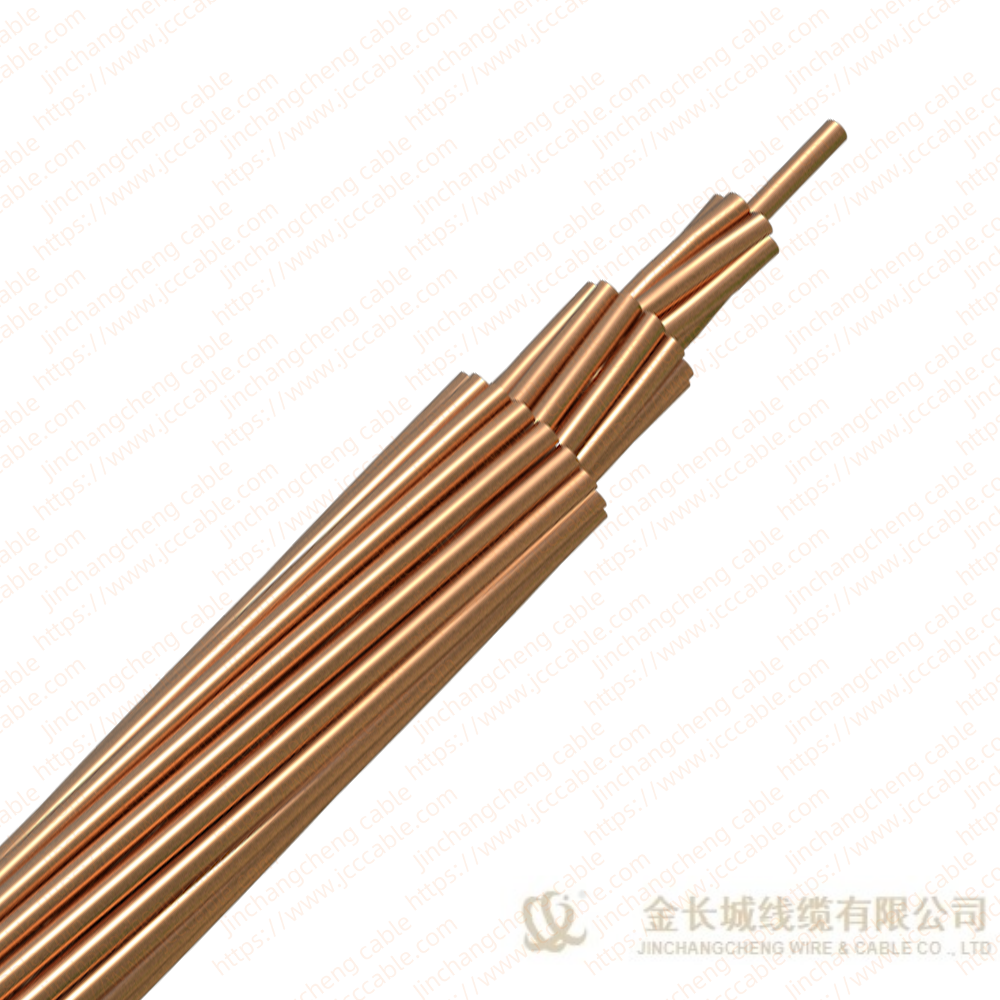

Application

Aluminum clad steel core aluminum stranded wire is mainly used for overhead lines, compared with ordinary steel core aluminum stranded wire, with light weight, high load, low power loss and other advantages, and anti-corrosion performance, erection and maintenance is convenient, long service life, large transmission capacity, good anti-corrosion performance. ACSR/AW Conductor is made of aluminum clad steel core reinforced core and aluminum wire stranded. There are ASTM standards, DIN standards and other manufacturing standards. It is widely used in transmission lines of various voltage levels and the transmission lines requiring the increase of Al-steel section ratio. It can also be used in the transmission lines of coastal areas, saline-alkali flats and third-grade and fourth-grade industrial pollution areas.

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products