MV Aluminum alloy cable

Key words:

Classification:

Product Description

Product Instruction

Aluminum aloy power cable makes up for the shortcomings of pure aluminum cable in the past, although it does not improve the electril.cal conductivity of the cable, but the bending performance, creep resistance and corrosion resistance are areaty improved, which can ensurethat the cable maintains continuous performance and stability when overloaded and overheated for a long time.

2.Standard

GB/T31840:1 ~ 3 ~ 2015 Rated voltage: 1kV(Um=1.2kV) to 35kV(Um=40kv) aluminum alloy extruded insulated power cable

3.Performance Characteristics

(1)Conductivity: The conductivity of aluminum alloy is about 61.8% of that of copper, and the current-carrying capacity is 79% of that of copper, which is better than the pure aluminum standard.

(2)Weight Advantage: Aluminum alloy cables are about half the weight of copper cables, making them easy to install and maintain and reducing installation costs.

(3)Mechanical properties: aluminum alloy cables have excellent creep resistance, tensile strength and elongation, as well as good flexibility.

(4)Corrosion resistance: Aluminum alloy cable can form an oxide layer on the surface, and the addition of rare earth elements can further improve the corrosion resistance, especially suitable for harsh environments.

(5)Coefficient of thermal expansion: The coefficient of thermal expansion of aluminum alloy is comparable to that of copper, making it suitable for use with copper conductor connectors.

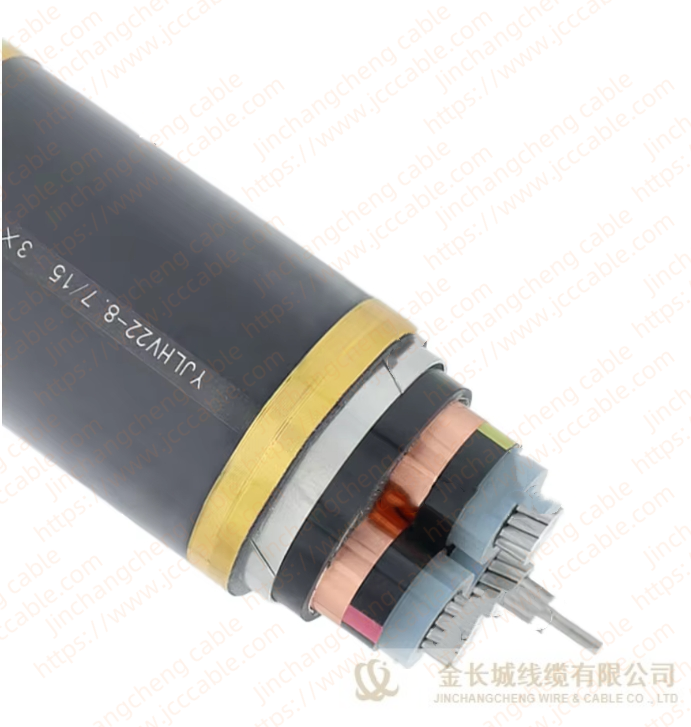

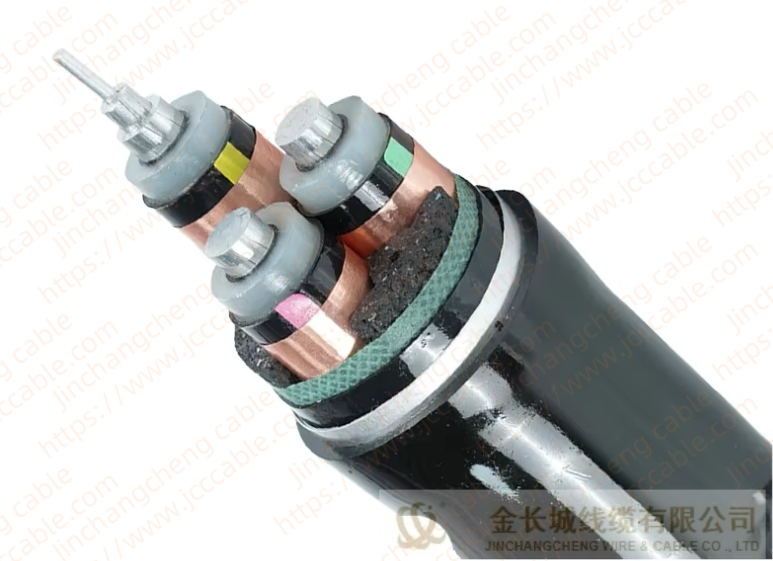

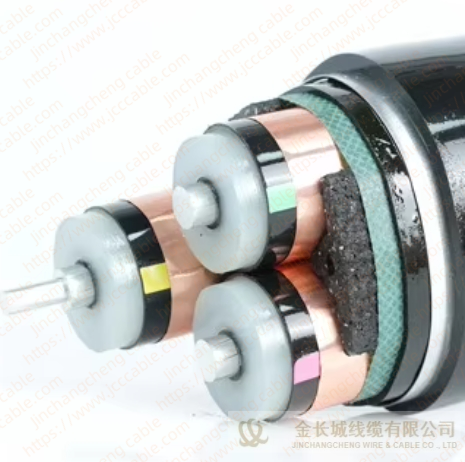

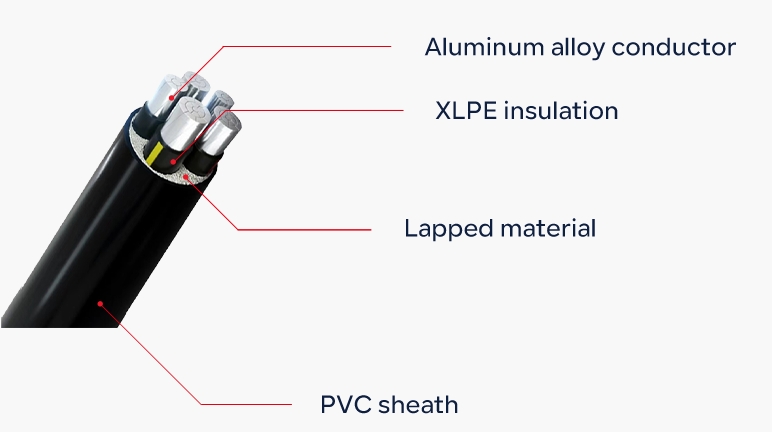

4.Product structure and parameters

Model | Name |

YJLHV | XLPE insulated PVC sheathed aluminum alloy power cable |

YJLH22 | XLPE insulated PVC sheathed steel tape armored aluminum alloy power cable |

VLHV | PE insulated PVC sheathed aluminum alloy power cable |

VLHV22 | PE insulated PVC sheathed aluminum alloy power cable |

Aluminum Alloy | Rated Voltage | |||||

0.6/1KV | 8.7/10KV | 26/35KV | ||||

8.7/15KV | ||||||

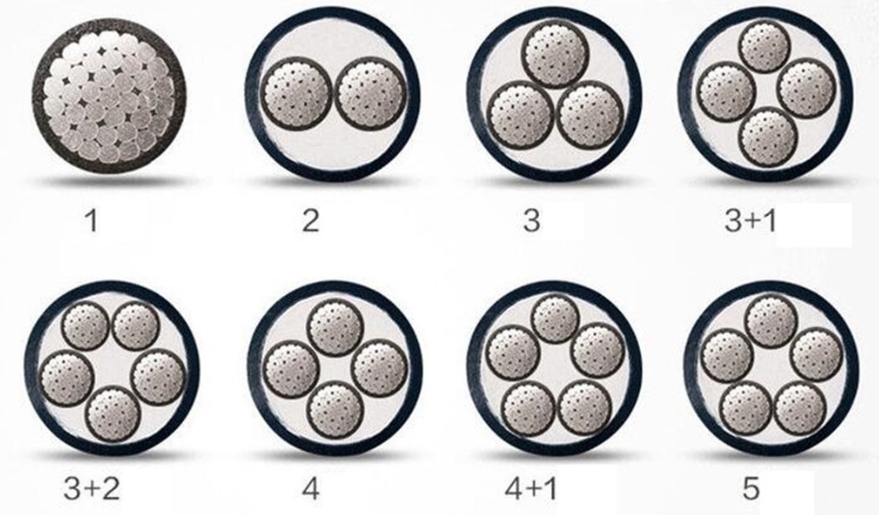

Nominal | Cores No. | Nominal Cross | Cores No | Nominal | Cores | |

YJHLV | 10~500 | 1,3,4,5 | 25~400 | 13 | 50~400 | 13 |

3+1 | ||||||

3+2 | ||||||

4+1 | ||||||

YJHLV22 | 10~500 | 1,3,4,5 | 25~400 | 13 | 50~400 | 13 |

3+1 | ||||||

3+2 | ||||||

4+1 | ||||||

Triangular segmental conductor (mm2) | Approximate cable size(mm) | |||||||

| 1core | 2core | 3core | 3+1core | 4core | 3+2core | 4+1core | 5core |

10 | 8.3 | 15.9 | 16.8 | 17.9 | 18.3 | 19.1 | 19.5 | 19.9 |

16 | 9.3 | 18 | 19.1 | 20.2 | 20.8 | 21.6 | 22.2 | 22.7 |

25 | 10.9 | 21.4 | 22.7 | 23.9 | 24.9 | 25.4 | 26.4 | 27.3 |

35 | 11.9 | 23.5 | 25 | 25.8 | 27.4 | 27.1 | 28.6 | 30.3 |

50 | 13.5 | 26.8 | 28.6 | 30.1 | 31.7 | 31.9 | 33.6 | 35.1 |

70 | 15.3 | 30.8 | 33.1 | 34.3 | 36.7 | 36.5 | 38.4 | 40.6 |

95 | 17.1 | 34.2 | 36.7 | 38.4 | 40.7 | 41.1 | 43.2 | 45 |

120 | 18.8 | 38 | 40.8 | 43.2 | 45.3 | 46.4 | 48.3 | 50.3 |

150 | 21.1 | 42.8 | 45.8 | 47.4 | 51 | 50.2 | 53.4 | 56.6 |

185 | 23.2 | 47 | 50.5 | 52.2 | 56.3 | 55.4 | 58.8 | 62.5 |

240 | 25.9 | 52.7 | 56.6 | 58.5 | 63 | 62 | 66.1 | 70 |

300 | 28.2 | 57.9 | 62.2 | 64.6 | 69.3 | 68.7 | 72.9 | 76.9 |

400 | 32.1 | 65.7 | 70.6 | 73.1 | 78.8 | 77.4 | 82.5 | 87.5 |

500 | 35.6 | 73 | 78.7 | 81.6 | 87.8 | 86.5 | 92.1 | 97.7 |

630 | 39.7 | 81.9 | 88.2 | 91.2 | 98.4 | 96.6 | 102.9 | 109.3 |

Triangular segmental conductor(mm2) | Approximate cable weight (kg/km) | |||||||

| 1core | 2core | 3core | 3+1core | 4core | 3+2core | 4+1core | 5core |

10 | 83 | 231 | 274 | 310 | 329 | 352 | 370 | 389 |

16 | 108 | 301 | 361 | 411 | 439 | 469 | 496 | 524 |

25 | 150 | 420 | 512 | 580 | 629 | 661 | 708 | 756 |

35 | 187 | 518 | 640 | 700 | 792 | 777 | 865 | 970 |

50 | 245 | 679 | 847 | 959 | 1071 | 1079 | 1203 | 1313 |

70 | 319 | 900 | 1145 | 1271 | 1448 | 1443 | 1598 | 1775 |

95 | 410 | 1137 | 1455 | 1638 | 1844 | 1875 | 2078 | 2265 |

120 | 500 | 1402 | 1798 | 2075 | 2281 | 2398 | 2599 | 2826 |

150 | 624 | 1767 | 2242 | 2494 | 2871 | 2808 | 3175 | 3553 |

185 | 762 | 2140 | 2749 | 3055 | 3517 | 3459 | 3883 | 4350 |

240 | 961 | 2705 | 3479 | 3386 | 4450 | 4363 | 4939 | 5502 |

300 | 1161 | 3304 | 4258 | 4753 | 5447 | 5388 | 6068 | 6733 |

400 | 1525 | 4284 | 5537 | 6162 | 7126 | 6934 | 7874 | 8804 |

500 | 1879 | 5291 | 6881 | 7682 | 8845 | 8664 | 9799 | 10969 |

630 | 2332 | 6621 | 8605 | 9573 | 11050 | 10816 | 12209 | 13694 |

5.Applications

1.Power Industry

Aluminum cables are widely used in transmission lines, substation contact lines, power distribution systems and other fields to ensure the stability and reliability of power transmission.

2.New Energy Development

Aluminum alloy cables support the large-scale transmission of new energy sources such as solar and wind energy, providing a reliable means of power transmission for the development and utilization of clean energy.

At the same time, aluminum alloy cables have good recyclability and reusability, in line with the requirements of sustainable development.

3.Industrial production

In factories, mines, manufacturing and other places, aluminum alloy cables are used for the electrical connection of various equipments and machines, adapting to high temperature, high humidity and other harsh working environments.

4.Transportation

Aluminum alloy cables can be used for the power supply of rail transportation systems such as subways and streetcars, as well as the power transmission of electric vehicle charging piles, supporting the sustainable development of urban transportation.

5.Residential and Commercial Buildings

Aluminum alloy cables are used to connect power supply, lighting, air-conditioning and other electrical equipment in residential and commercial buildings, hospitals, schools, libraries and other public facilities, reducing construction costs and ensuring electrical safety.

6.Special Occasions

In high-rise buildings, ancient buildings, military bases, aerospace and other special occasions, aluminum alloy cable’s lightweight and high-strength characteristics make it an ideal choice for electrical wiring.

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province