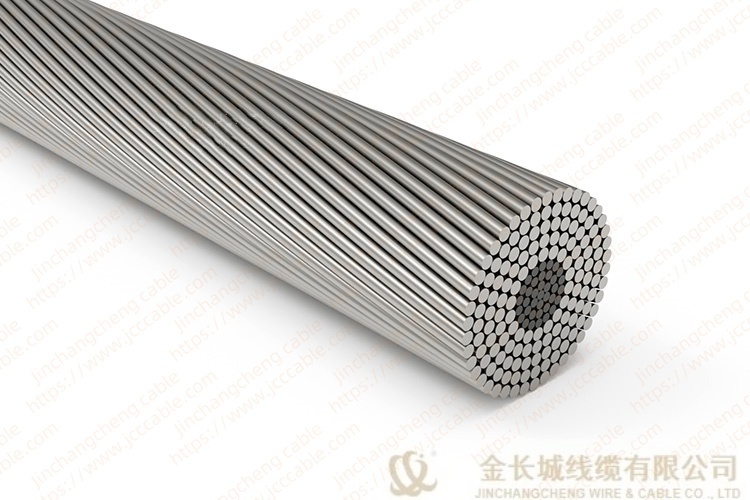

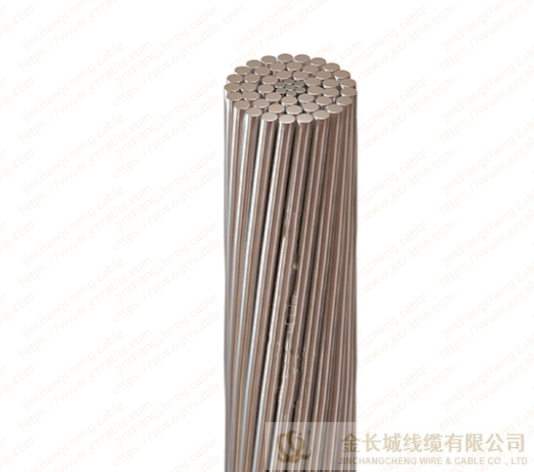

AACSR-Aluminum Alloy Conductor Steel Reinforced

Key words:

Classification:

Product Description

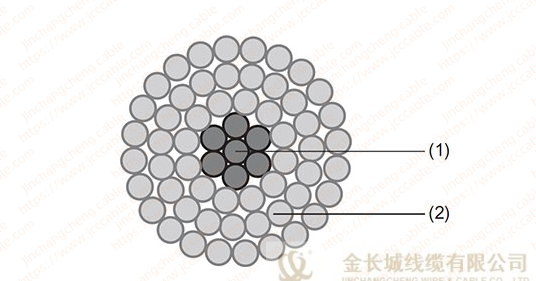

AACSR is a concentrically stranded conductor composed of one or more layers of Aluminium -Magnesium -Silicon Alloy wire stranded around a high strength coated steel core. The core can be of either single wire or stranded multi wire. Additional corrosion protection is available through the application of grease to the core or infusion of the complete cable with grease.

Standard

IEC 61089 Round wire concentric lay overhead electrical stranded conductors

GB/T 1179 Round wire concentric lay overhead electrical stranded conductors

Product structure and parameter

AACSR / A2/S1A A2/S3A IEC 61089 | ||||||||||||||

Code Number | Steel Ratio | Areas | No.of Wires | Wire Diameter | Diameter | Linear Mass | Rated Strength | D.C. Resistance | ||||||

Al. Alloy | Steel | Total | Al. Alloy | Steel | Al. Alloy | Steel | Core | Cond. | A2/S1A | A2/S3A | ||||

| % | mm² | mm² | mm² | | | mm | mm | mm | mm | kg/km | KN | KN | Ω/km |

16 | 17 | 18.4 | 3.07 | 21.5 | 6 | 1 | 1.98 | 1.98 | 1.98 | 5.93 | 74.4 | 9.02 | 9.88 | 1.7934 |

25 | 17 | 28.8 | 4.8 | 33.6 | 6 | 1 | 2.47 | 2.47 | 2.47 | 7.41 | 116.2 | 13.96 | 15.25 | 1.1478 |

40 | 17 | 46 | 7.67 | 53.7 | 6 | 1 | 3.13 | 3.13 | 3.13 | 9.38 | 185.9 | 22.02 | 24.17 | 0.7174 |

63 | 17 | 72.5 | 12.1 | 84.6 | 6 | 1 | 3.92 | 3.92 | 3.92 | 11.8 | 292.8 | 34.68 | 37.58 | 0.4555 |

100 | 6 | 115 | 6.39 | 121 | 18 | 1 | 2.85 | 2.85 | 2.85 | 14.3 | 366.4 | 41.24 | 42.97 | 0.288 |

125 | 6 | 144 | 7.99 | 152 | 18 | 1 | 3.19 | 3.19 | 3.19 | 16 | 458 | 51.23 | 53.47 | 0.2304 |

125 | 16 | 144 | 23.4 | 167 | 26 | 7 | 2.65 | 2.06 | 6.19 | 16.8 | 579.9 | 69.86 | 76.42 | 0.231 |

160 | 6 | 184 | 10.2 | 194 | 18 | 1 | 3.61 | 3.61 | 3.61 | 18 | 586.2 | 65.58 | 68.03 | 0.18 |

160 | 16 | 184 | 30 | 214 | 26 | 7 | 3 | 2.34 | 7.01 | 19 | 742.3 | 88.52 | 96.61 | 0.1805 |

200 | 6 | 230 | 12.8 | 243 | 18 | 1 | 4.04 | 4.04 | 4.04 | 20.2 | 732.8 | 81.97 | 85.04 | 0.144 |

200 | 16 | 230 | 37.5 | 268 | 26 | 7 | 3.36 | 2.61 | 7.83 | 21.3 | 927.9 | 110.64 | 120.77 | 0.1444 |

250 | 10 | 288 | 28.3 | 316 | 22 | 7 | 4.08 | 2.27 | 6.8 | 23.1 | 1013.5 | 117.09 | 124.72 | 0.1154 |

250 | 16 | 288 | 46.9 | 335 | 26 | 7 | 3.75 | 2.92 | 8.76 | 23.8 | 1159.8 | 138.31 | 150.96 | 0.1155 |

315 | 7 | 363 | 25.1 | 388 | 45 | 7 | 3.2 | 2.14 | 6.41 | 25.6 | 1196.5 | 136.28 | 143.3 | 0.0917 |

315 | 16 | 363 | 59 | 422 | 26 | 7 | 4.21 | 3.28 | 9.83 | 26.7 | 1461.4 | 171.9 | 188.44 | 0.0 |

AACSR / JLHA1/G1A,JLHA1/G2A,JLHA1/G3A GB/T 1179 | |||||||||||||||

Code Number | Steel Ratio | Calculated Area | No.of Wires | Wire Diameter | Diameter | Linear Mass | Rated Strength | D.C. Resistance at 20℃ | |||||||

Al. Alloy | Steel | Total | Al. Alloy | Steel | Al. Alloy | Steel | Steel | Cond. | JLHA1/ | JLHA1/ | JLHA1/ | ||||

| % | mm² | mm² | mm² | | | mm | mm | mm | mm | kg/km | KN | KN | KN | Ω/km |

10/2 | 16.7 | 10.6 | 1.78 | 12.4 | 6 | 1 | 1.5 | 1.5 | 1.5 | 4.5 | 42.8 | 5.51 | 5.76 | 6.01 | 3.1444 |

16/3 | 16.7 | 16.1 | 2.69 | 18.8 | 6 | 1 | 1.85 | 1.85 | 1.85 | 5.55 | 65.2 | 8.93 | 8.76 | 9.14 | 2.0671 |

35/6 | 16.7 | 34.9 | 5.81 | 40.7 | 6 | 1 | 2.72 | 2.72 | 2.72 | 8.16 | 140.9 | 17.96 | 18.77 | 19.52 | 0.9563 |

50/8 | 16.7 | 48.3 | 8.04 | 56.3 | 6 | 1 | 3.2 | 3.2 | 3.2 | 9.6 | 195 | 24.53 | 25.66 | 26.78 | 0.6909 |

50/30 | 58.3 | 50.7 | 29.6 | 80.3 | 12 | 7 | 2.32 | 2.32 | 6.96 | 11.6 | 371.3 | 50.22 | 54.36 | 58.21 | 0.6614 |

70/10 | 16.7 | 68 | 11.3 | 79.3 | 6 | 1 | 3.8 | 3.8 | 3.8 | 11.4 | 275 | 33.91 | 34.70 | 36.63 | 0.4899 |

70/40 | 58.3 | 69.7 | 40.7 | 110 | 12 | 7 | 2.72 | 2.72 | 8.16 | 13.6 | 510.4 | 69.03 | 74.73 | 80.01 | 0.4812 |

95/15 | 16.2 | 94.4 | 15.3 | 110 | 26 | 7 | 2.15 | 1.67 | 5.01 | 13.6 | 380.5 | 48.62 | 50.76 | 52.91 | 0.3554 |

95/20 | 19.8 | 95.1 | 18.8 | 114 | 7 | 7 | 4.16 | 1.85 | 5.55 | 13.9 | 408.5 | 51.98 | 54.62 | 57.25 | 0.3509 |

95/55 | 58.3 | 96.5 | 56.3 | 153 | 12 | 7 | 3.2 | 3.2 | 9.6 | 16 | 706.4 | 93.29 | 101.20 | 109.1 | 0.3477 |

120/7 | 5.6 | 119 | 6.61 | 125 | 18 | 1 | 2.9 | 2.9 | 2.9 | 14.5 | 378.9 | 46.17 | 47.1 | 47.95 | 0.2815 |

120/20 | 16.3 | 116 | 18.8 | 134 | 26 | 7 | 2.38 | 1.85 | 5.55 | 15.1 | 466.4 | 59.61 | 62.24 | 64.88 | 0.29 |

120/25 | 19.8 | 122 | 24.2 | 147 | 7 | 7 | 4.72 | 2.1 | 6.3 | 15.7 | 526 | 66.95 | 70.34 | 73.74 | 0.2726 |

120/70 | 58.3 | 122 | 71.3 | 193 | 12 | 7 | 3.6 | 3.6 | 10.8 | 18 | 894 | 116.9 | 121.80 | 134 | 0.2747 |

Application

Used as bare overhead transmission conductor and as primary and secondary distribution conductor and messenger support. ACSR conductors where the aluminum wires are replaced with the high strength aluminum alloy material. These super high strength conductors are used in river crossings or for long span applications where the traditional ACSR conductor will not work.

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province