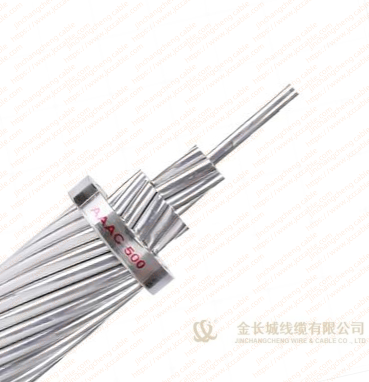

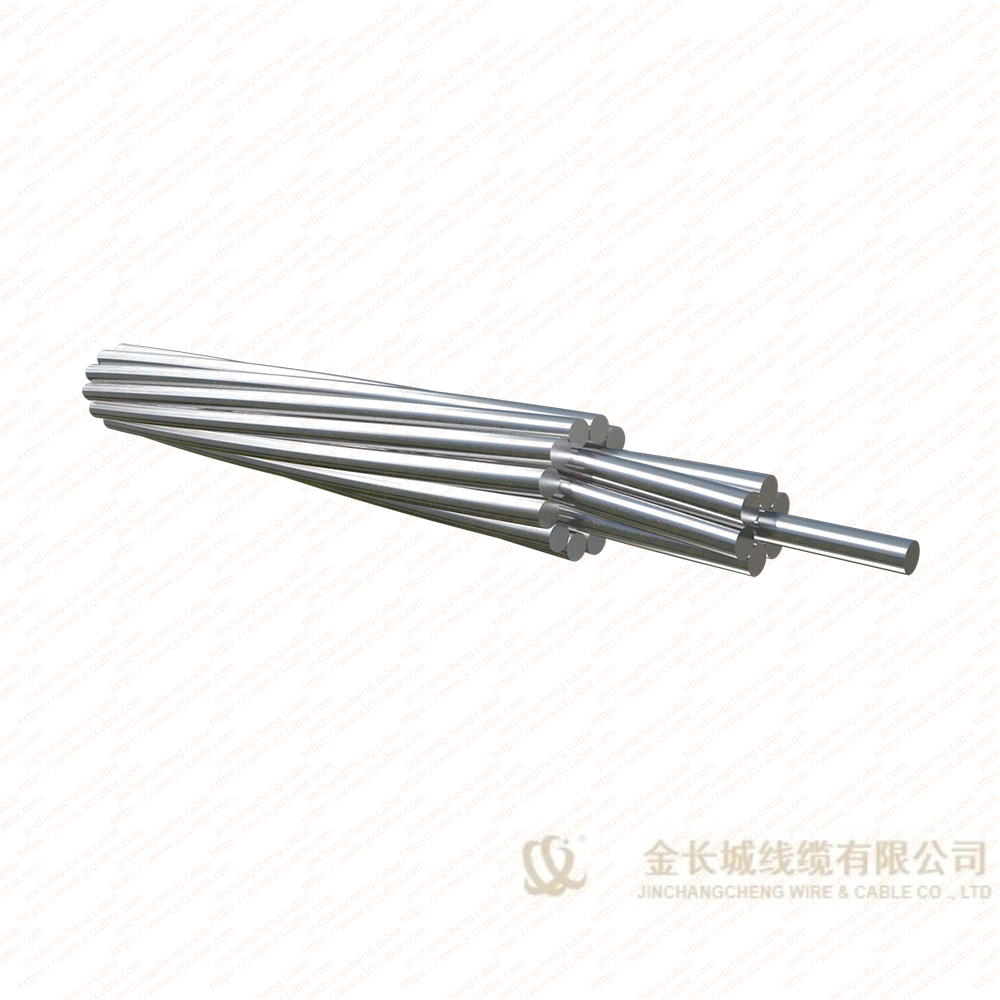

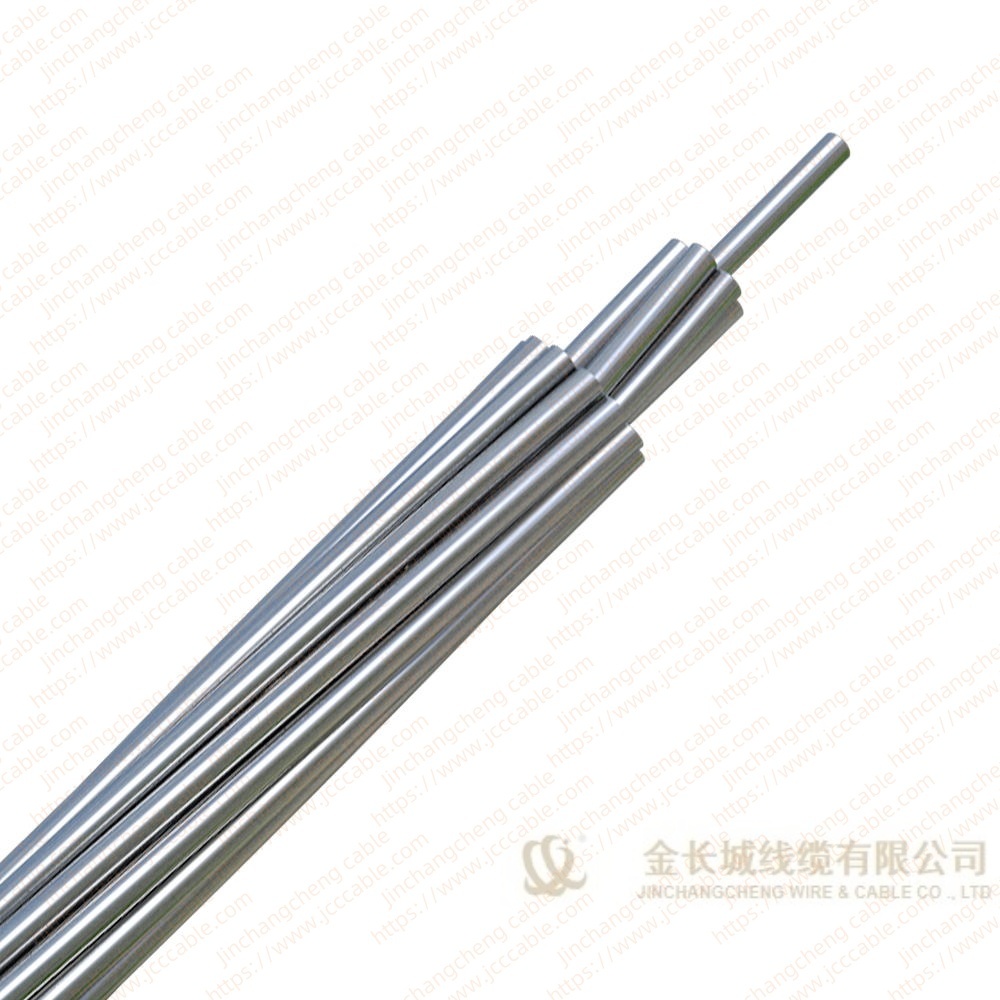

AAAC-All Aluminum Alloy Stranded Conductor

Key words:

Classification:

Product Description

Description

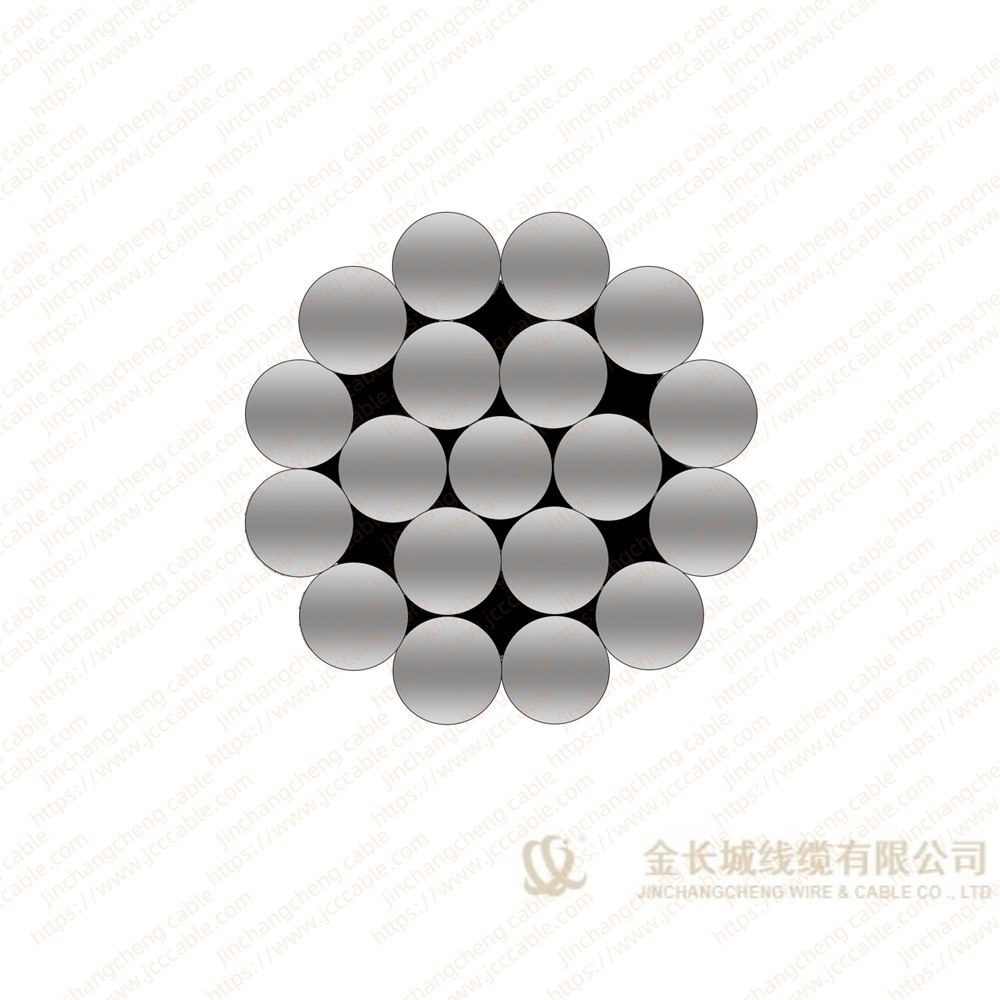

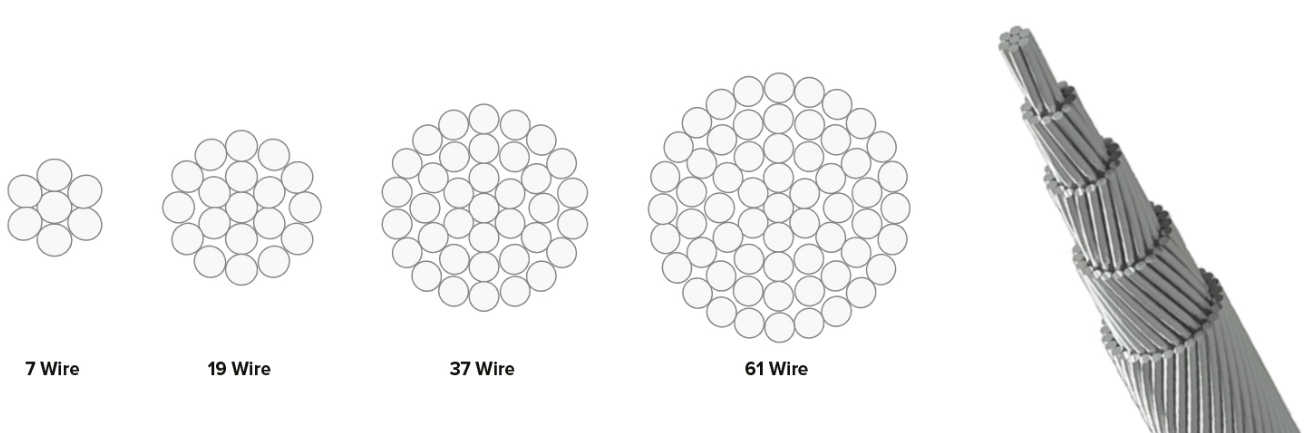

The bare-core stranded conductor is made of heat treated aluminium-magnesium-silicon alloy wires.

Two types of aluminium-magnesium-silicon alloy wires have different mechanical and electrical properties. The two types are designated Type A and Type B respectively.

Conductors are made of combinations of the following wires:

- aluminium alloy type B as per IEC 60104, designated A2;

- aluminium alloy type A as per IEC 60104, designated A3.

Specification

IEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded Conductors

GB/T 1179 Round Wire Concentric Lay Overhead Electrical Stranded Conductors

Features

1.Good corrosion resistance

AAAC has good corrosion resistance because it consists only of aluminum alloy wires.It has better corrosion resistance than ACSR.

2.Better strength to weight ratio

Compared with ACSR,AAAC can get better strength to weight ratio and provide improved electrical properties.

Product structure and parameter

GB/T 1179-1999

Code Number | Stranding Wire Diameter | Approx | Sectional Area | Approx Weight | Breaking Load | DC Resistance | |||

Overall | |||||||||

Al | Steel | Diameter | Al | Steel | Total | ||||

mm | mm | mm | mm 2 | mm 2 | mm 2 | Kg/km | KN | Ohm/km | |

16 | 6/1.84 | 1/1.84 | 5.53 | 16 | 2.67 | 18.7 | 64.6 | 6.08 | 1.7934 |

25 | 6/2.30 | 1/2.30 | 6.91 | 25 | 4.17 | 29.2 | 100.9 | 9.13 | 1.1478 |

100 | 6/4.61 | 1/4.61 | 13.8 | 100 | 16.7 | 117 | 403.8 | 34.33 | 0.2869 |

125 | 18/2.97 | 1/2.97 | 14.9 | 125 | 6.94 | 132 | 397.9 | 29.17 | 0.2304 |

160 | 18/3.36 | 1/3.36 | 16.8 | 160 | 8.89 | 169 | 509.3 | 36.18 | 0.18 |

250 | 22/3.80 | 7/2.11 | 21.6 | 250 | 24.6 | 275 | 880.6 | 68.72 | 0.1154 |

400 | 54/3.07 | 7/3.07 | 27.6 | 400 | 51.9 | 452 | 1510.3 | 123.04 | 0.0723 |

450 | 54/3.26 | 7/3.26 | 29.3 | 450 | 58.3 | 508 | 1699.1 | 138.42 | 0.0643 |

500 | 54/3.43 | 7/3.43 | 30.9 | 500 | 64.8 | 565 | 1887.9 | 153.8 | 0.0578 |

560 | 54/3.63 | 19/2.18 | 32.7 | 560 | 70.9 | 631 | 2103.4 | 172.59 | 0.0516 |

630 | 54/3.85 | 19/2.31 | 34.7 | 630 | 79.8 | 710 | 2366.3 | 191.77 | 0.0459 |

710 | 54/4.09 | 19/2.45 | 36.8 | 710 | 89.9 | 800 | 2666.8 | 216.12 | 0.0407 |

800 | 72/3.76 | 7/2.51 | 37.6 | 800 | 34.6 | 835 | 2480.2 | 167.41 | 0.0361 |

900 | 72/3.99 | 7/2.66 | 39.9 | 900 | 39.9 | 939 | 2790.2 | 188.33 | 0.0321 |

AAAC/A2 IEC 61089 | |||||||

Code Number | Area | No.of Wires | Diameter | Linear Mass | Rated Strength | D.C. Resistance | |

Wire | Cond. | ||||||

| mm² | | mm | mm | kg/km | KN | Ω/km |

16 | 18.4 | 7 | 1.83 | 5.49 | 50.4 | 5.43 | 1.7896 |

25 | 28.8 | 7 | 2.29 | 6.86 | 78.7 | 8.49 | 1.1453 |

40 | 46 | 7 | 2.89 | 8.68 | 125.9 | 13.58 | 0.7158 |

63 | 72.5 | 7 | 3.63 | 10.9 | 198.3 | 21.39 | 0.4545 |

100 | 115 | 19 | 2.78 | 13.9 | 316.3 | 33.95 | 0.2877 |

125 | 144 | 19 | 3.1 | 15.5 | 395.4 | 42.44 | 0.2302 |

160 | 184 | 19 | 3.51 | 17.6 | 506.1 | 54.32 | 0.1798 |

200 | 230 | 19 | 3.93 | 19.6 | 632.7 | 67.91 | 0.1439 |

250 | 288 | 19 | 4.39 | 22 | 790.8 | 84.88 | 0.1151 |

315 | 363 | 37 | 3.53 | 24.7 | 998.9 | 106.95 | 0.0916 |

400 | 460 | 37 | 3.98 | 27.9 | 1268.4 | 135.81 | 0.0721 |

450 | 518 | 37 | 4.22 | 29.6 | 1426.9 | 152.79 | 0.0641 |

500 | 575 | 37 | 4.45 | 31.2 | 1585.5 | 169.76 | 0.0577 |

560 | 645 | 61 | 3.67 | 33 | 1778.4 | 190.14 | 0.0516 |

Application

AAAC is used as a bare overhead conductor for power transmission and distribution lines, on aerial circuits that require a larger mechanical resistance than AAC, and a better corrosion resistance than ACSR. The sag characteristics and the strength-to-weight ratio of AAAC is better than both AAC / ACSR.

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province